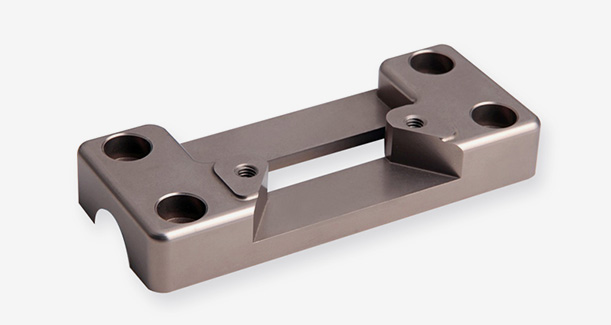

Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

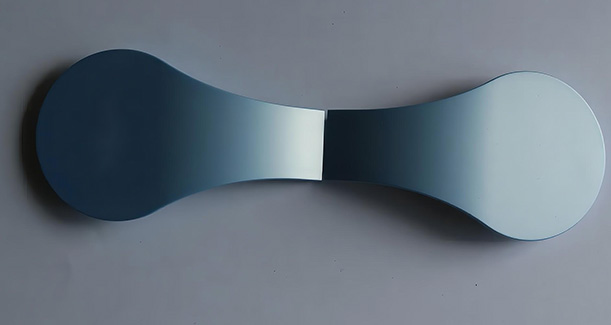

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.