Views: 5 Author: Site Editor Publish Time: 2024-04-16 Origin: Site

In the realm of automotive manufacturing, producing high-quality components while managing production costs efficiently is a paramount concern. This comprehensive guide delves into the intricacies of automotive component production, focusing on strategies to optimize production costs and enhance efficiency for sustainable growth and competitiveness.

1. Understanding Automotive Component Production

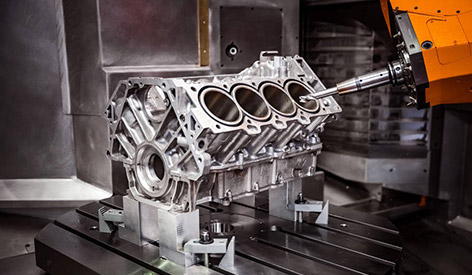

Automotive component production encompasses the manufacturing processes involved in creating various parts and assemblies used in vehicles. These components range from engine parts and chassis components to interior and exterior elements, each playing a critical role in vehicle performance, safety, and aesthetics.

2. Key Factors Influencing Production Costs

Material Selection: Choosing the right materials based on performance requirements, cost-effectiveness, and regulatory compliance.

Manufacturing Processes: Selecting appropriate manufacturing techniques such as casting, forging, machining, and injection molding based on part complexity, volume, and cost considerations.

Labor Costs: Optimizing labor utilization, skill levels, and workforce efficiency to minimize labor costs while maintaining quality.

Supply Chain Management: Streamlining supply chains, reducing lead times, and negotiating favorable terms with suppliers to control material costs.

Equipment and Technology: Investing in advanced machinery, automation, and digital tools to improve production efficiency, reduce downtime, and enhance quality control.

Energy Consumption: Implementing energy-efficient practices and technologies to reduce operational costs and environmental impact.

3. Strategies for Enhancing Production Efficiency

Lean Manufacturing Principles: Implementing lean methodologies to eliminate waste, optimize workflow, and improve overall production efficiency.

Continuous Improvement: Encouraging a culture of continuous improvement, innovation, and knowledge sharing to drive efficiency gains and cost savings.

Quality Management Systems: Implementing robust quality management systems, including ISO standards, to ensure consistent product quality and reduce defects and rework.

Automation and Robotics: Leveraging automation, robotics, and AI-driven technologies for repetitive tasks, assembly processes, and quality inspection to enhance speed and accuracy while reducing labor costs.

Data Analytics: Harnessing data analytics and real-time monitoring to identify production bottlenecks, optimize resource allocation, and make data-driven decisions for process improvements.

Supplier Collaboration: Collaborating closely with suppliers for Just-in-Time (JIT) deliveries, quality assurance, and cost-effective procurement of materials and components.

4. Balancing Cost and Quality

Achieving a balance between production costs and quality is crucial for automotive component manufacturers. Cost reduction initiatives should not compromise product quality, safety, or compliance with industry standards and regulations. Strategies such as value engineering, design for manufacturability, and total cost of ownership analysis can help optimize costs without sacrificing quality or performance.

5. Future Trends and Innovations

The automotive industry is evolving rapidly, driven by technological advancements and market demands. Key trends shaping the future of automotive component production include:

Electric and Autonomous Vehicles: Increasing demand for components related to electric powertrains, autonomous driving systems, and connectivity solutions.

Lightweight Materials: Adoption of lightweight materials such as aluminum, composites, and advanced plastics to improve fuel efficiency and reduce emissions.

Digitalization and Industry 4.0: Integration of digital technologies, IoT, cloud computing, and predictive analytics for smart manufacturing, predictive maintenance, and supply chain optimization.

Sustainability: Embracing sustainable practices, circular economy principles, and green manufacturing initiatives to minimize environmental impact and meet regulatory requirements.

6. Conclusion

Optimizing automotive component production requires a strategic approach that balances cost considerations with efficiency, quality, and innovation. By leveraging advanced technologies, best practices in manufacturing, and a proactive mindset towards continuous improvement, automotive manufacturers can stay competitive, resilient, and future-ready in an ever-evolving industry landscape.

This article covers the essential aspects of optimizing production costs and efficiency in automotive component manufacturing, addressing key factors, strategies, and future trends. Let me know if you need further adjustments or additional information!