ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-26 Origin: Site

Your part needs to be flexible and soft, like rubber. But it also needs to be tough enough to survive constant scraping and impact, like a hard plastic. What do you choose?

This is a classic engineering trade-off. Rubber is soft, but it wears out quickly. Hard plastic is durable, but it can be brittle and crack under impact.

But what if you did not have to choose? What if there was a material that offered the best of both worlds? This is the power of Thermoplastic Polyurethane, or TPU. And the process to shape it is tpu injection molding.

content:

The problem with traditional rubber is durability. It provides great grip and flexibility, but it can tear and wear down quickly when subjected to friction.

The problem with a standard hard plastic is brittleness. It is very durable against smooth wear, but it cannot handle sudden shocks or impacts. It will crack.

TPU was invented to solve this exact problem. It is a unique "hybrid" material that bridges the gap between these two worlds.

TPU is a type of TPE, or Thermoplastic Elastomer. As the name suggests, it has the properties of both a thermoplastic and an elastomer.

Like a thermoplastic, it is supplied as hard, solid pellets. It can be melted, molded, and then re-melted. This is what makes tpu injection molding possible using standard high-pressure machines. This is a huge advantage over thermoset rubbers, which cannot be re-melted.

Like an elastomer (rubber), its final, solid form is soft, flexible, and elastic. It can be stretched to a huge degree and it will spring back to its original shape. Just like a rubber band.

This dual personality is what makes TPU so incredibly versatile.

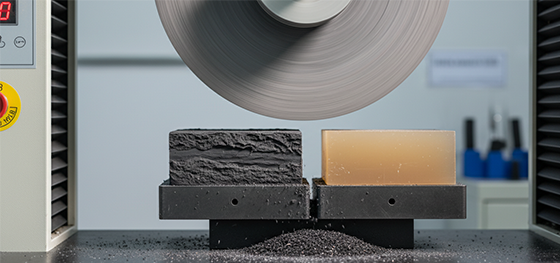

The first and most famous superpower of TPU is its incredible resistance to abrasion. It is one of the toughest materials out there when it comes to friction and wear.

A part made from TPU can withstand constant scraping, rubbing, and grinding that would destroy most other polymers.

This is why it is the number one choice for high-wear industrial applications. The wheels on a heavy-duty cart or a factory robot are made from TPU. The protective cable sheathing that gets dragged across a factory floor is made from TPU. The liners for chutes that handle abrasive minerals are made from TPU.

When you need a part that simply will not wear out, you choose TPU.

The second superpower is its unique combination of toughness and elasticity. This means it can absorb huge impacts without breaking, and then return to its original shape.

This is why it is a dominant material in consumer products. A high-quality protective phone case is made from TPU. It is soft enough to cushion the phone from a drop, but tough enough that the case itself does not crack.

High-end watch bands for sports watches are made from TPU. They are comfortable and flexible against the skin, but they are also incredibly strong and resistant to tearing.

This is a different kind of strength. It is not about being rigid and unmoving. It is about being resilient.

While it can be used in standard machines, successful tpu injection molding requires specific expertise.

The most important factor is moisture control. TPU is "hygroscopic," which means it loves to absorb moisture from the air. If you try to mold TPU pellets that have not been properly dried, the moisture will turn to steam in the hot machine barrel. This will ruin the part. It will cause bubbles and splay marks on the surface. A professional manufacturer must use special drying equipment to prepare the material.

The mold design is also critical. Because TPU is so flexible, ejecting the finished part from the mold can be tricky. It can stretch or tear if the ejector pins are not in the right place.

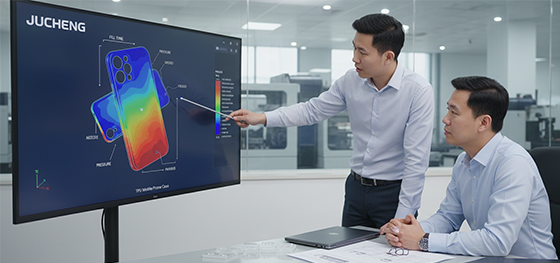

This is where a partner like JUCHENG adds value. We use Moldflow simulation software to predict how the TPU will behave. We can optimize the mold design to ensure your parts are made efficiently and without defects. This is the expertise that turns a great material into a great product.