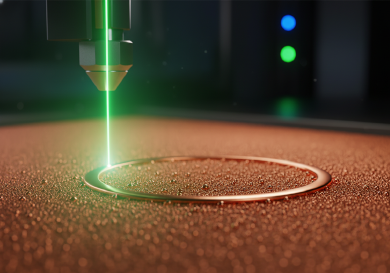

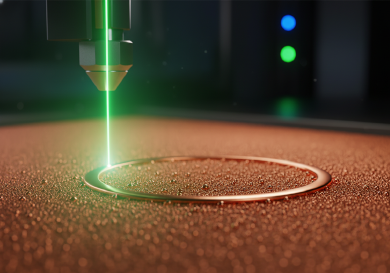

2026-02-03 Wrestling with pure copper in an additive environment feels like trying to melt a mirror with a flashlight. In the traditional hierarchy of metal 3d printing, copper is the ultimate rebel. While titanium and steel cooperate with standard infrared lasers, copper reflects nearly 95% of that energy, se

Read More

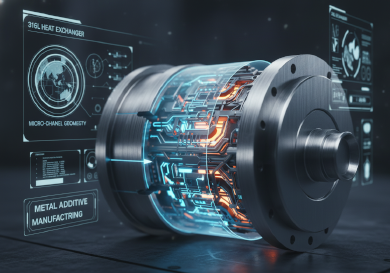

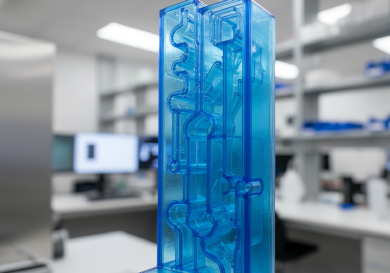

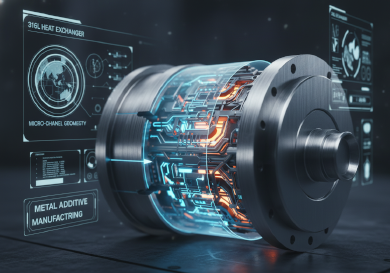

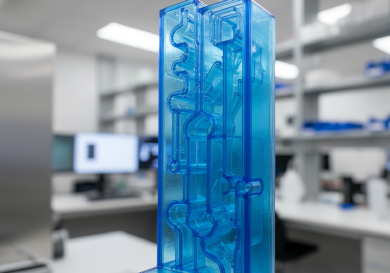

2026-02-03 Corrosion is a slow, patient predator that feeds on industrial stagnation. In the high-demand sectors of chemical processing and maritime engineering, standard components often fail because their internal surfaces were never intended to face aggressive reagents. Traditional subtractive methods reach

Read More

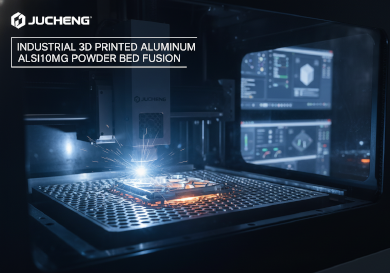

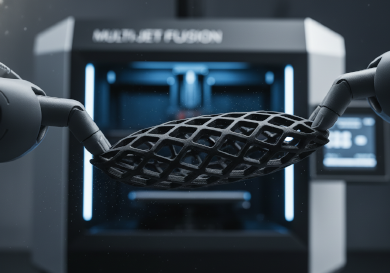

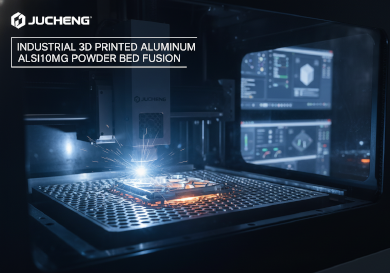

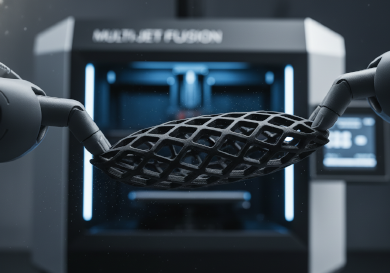

2026-02-03 Weight is a silent tax on every moving mechanism. In the high-velocity sectors of aerospace, robotics, and electric vehicle development, the struggle to shed kilograms without compromising structural stiffness is an eternal engineering battle. Traditional aluminum casting, while effective for bulk s

Read More

2026-02-03 Shaping the strongest metal in the world used to be a battle of attrition. Titanium is legendary for its refusal to cooperate on a machine bed; it eats carbide tools, work-hardens instantly, and traps heat with a persistence that challenges every traditional machinist. But the arrival of 3d printed

Read More

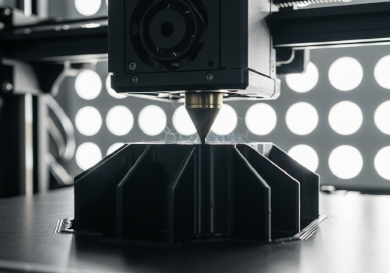

2026-02-03 Stability in manufacturing is often found in the middle ground between extremes. While the 3d printing plastic world is frequently split between the easy-to-use but brittle PLA and the strong but warp-prone ABS, a specific copolymer has quietly become the primary sanctuary for functional hardware. T

Read More

2026-02-03 Sunlight is a slow poison for most polymers. In the competitive landscape of the 3d printing plastic industry, engineers often fall into the trap of using standard ABS for functional prototypes meant for field service. Within six months, those parts yellow, become brittle, and eventually shatter und

Read More

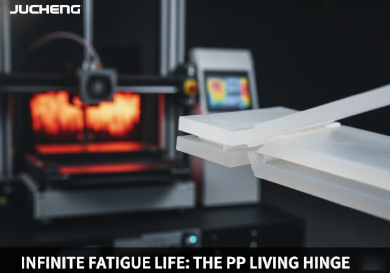

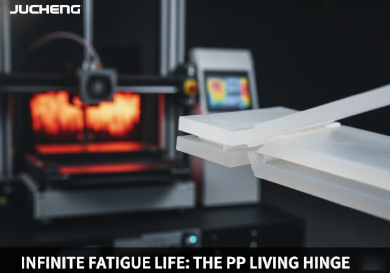

2026-02-02 Some engineering problems cannot be solved with sheer hardness. When a design requires a component to bend a million times without snapping, or to hold aggressive battery acids without dissolving, standard rigid polymers reach a physical dead-end. This is where pp 3d printing enters the manufacturin

Read More

2026-02-02 Rigidity is the standard goal of engineering, but survival often depends on the ability to yield. In the expansive palette of 3d printing plastic, most materials are built to resist force, yet there is a specialized tier designed to absorb, dissipate, and return energy. This is the sophisticated wor

Read More

2026-02-02 Touch a high-end consumer electronic device or the dashboard of a modern vehicle, and you are likely touching Acrylonitrile Butadiene Styrene. In the global 3d printing plastic ecosystem, ABS remains the definitive benchmark for what a functional plastic component should feel like. While newer polym

Read More

2026-02-02 Safety in the stratosphere is not a variable; it is a hard-coded technical requirement. When an aircraft interior component or an under-the-hood automotive bracket is designed, the primary fear is not just structural failure, but the danger of fire. In the vast catalog of the 3d printing plastic ind

Read More