ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-26 Origin: Site

Imagine designing a product not as an assembly of small pieces, but as a single, seamless, monolithic form. A car door with no separate trim pieces. A chair that flows from leg to backrest in one unbroken curve.

For decades, this vision was mostly a dream for designers. The immense cost and limitations of traditional manufacturing for large parts made it impossible for all but the most expensive projects.

This is the barrier that rim molding was born to break. It is a technology that empowers designers to think big. To think in single, beautiful forms. It is a process that liberates design from the tyranny of the seam.

content:

Seams are a compromise. They are a visual interruption. They are a potential point of weakness. They are often a sign that a product had to be broken into smaller, manufacturable pieces.

A seamless, monolithic design feels more honest. More elegant. Stronger. It feels like the product was born, not just assembled.

The ability to create huge, single-piece moldings is the superpower of rim molding. It allows a designer to maintain the integrity of their original vision. An entire car bumper, a massive piece of medical equipment housing, or a sleek chaise lounge can be created as one continuous part.

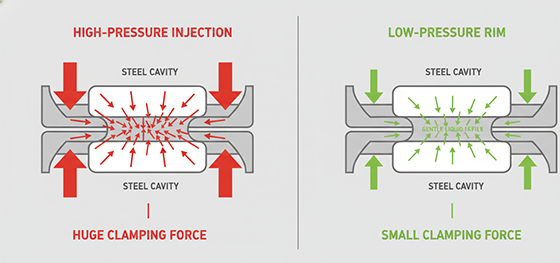

Why is this process so good at making large parts? The secret is low pressure.

The "RIM" in rim molding stands for reaction injection molding. Unlike traditional injection molding that uses extreme physical force to inject molten plastic, RIM uses a gentle chemical process.

Two liquids mix and flow into the mold at a pressure that is often 100 times lower than high-pressure injection molding. This means the force trying to push the mold apart is also 100 times lower.

This has huge implications. You do not need a gigantic, multi-million dollar machine with thousands of tons of clamping force to make a large part. A much smaller, less expensive machine can do the job. The process itself is simply more scalable to large dimensions.

The low pressure also revolutionizes the mold itself. This is the great enabler of large-part design freedom.

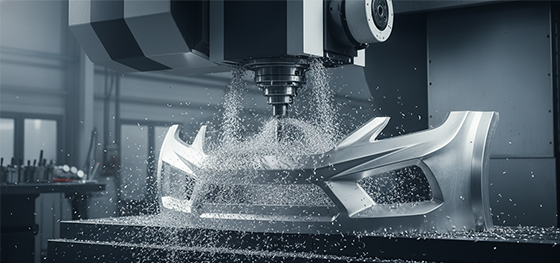

A traditional injection mold for a car bumper must be made from tons of hardened steel to withstand the immense pressure. It is incredibly expensive and can take half a year to build.

A rim molding tool for the same bumper can be made from a much lighter and cheaper material: aluminum. Aluminum is much faster to CNC machine than steel.

This means the tooling is a fraction of the cost. And it can be made in a fraction of the time. This is what makes it economically feasible for a company to produce a few hundred or a few thousand large parts. It breaks the financial prison of steel tooling.

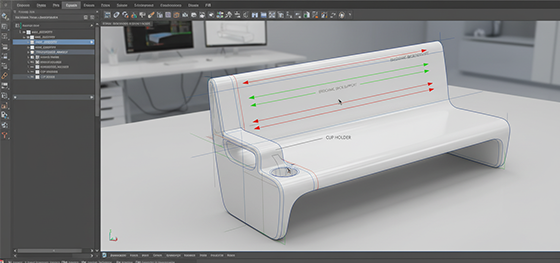

Knowing that you are free from the usual constraints allows you to design differently. You can think more holistically.

Instead of designing a panel and then figuring out how to attach a handle, you can design the handle as a seamless, integrated feature of the panel itself.

You can create deep ribs and bosses for structural support without worrying about the sink marks that would plague a traditional molding process. You can design with dramatic changes in wall thickness, from thin and elegant to thick and solid, all in the same part.

This freedom to integrate features and vary thickness allows a designer to create a smarter, stronger, and often more elegant part with a lower total part count.

So, what does this all mean for your next big idea?

It means you do not have to compromise. That huge, flowing, seamless shape you have imagined is not impossible. That complex, multi-functional enclosure does not need to be a clumsy assembly of a dozen smaller parts.

Rim molding is a process that meets you at the level of your ambition. A good manufacturing partner with deep expertise in this technology can be your greatest creative ally.

At JUCHENG, we can help you turn your most ambitious visions into large, beautiful, and tangible realities. We can help you design beyond the seam.