ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-26 Origin: Site

Your new protective case has a beautiful foam insert. It holds the product perfectly. But after a few uses, a disaster. The foam starts to tear. It feels lifeless. It loses its bounce. It no longer holds the product securely.

What went wrong? You specified a foam material. But not all foams are created equal. You have just become a victim of choosing the wrong grade of a very special material.

This is a deep dive into the world of eva foam injection molding. We are going to act like detectives. We will investigate why it fails, and what secrets you need to know to make it succeed.

content:

EVA stands for Ethylene Vinyl Acetate. It is a polymer known for its incredible softness, flexibility, and shock-absorbing personality. It is the material that puts the cushion in your running shoes.

But when it fails, it fails badly. A low-quality EVA foam will tear easily. Imagine the foam lining in a professional camera case. If the foam tears, the expensive camera is no longer protected.

An even more common failure is a loss of "rebound." The foam gets squashed, but it does not bounce back. It becomes flat and hard. The cushioning is gone. To understand why this happens, we need to look inside the foam.

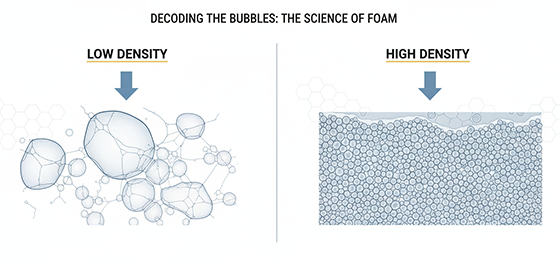

EVA is a "closed-cell" foam. This means it is made of millions of tiny, individual bubbles, or "cells," all trapped inside the plastic. These bubbles are filled with gas.

When you press on the foam, you are squeezing these tiny balloons. They are what provide the cushioning. The properties of the foam are completely dependent on the size and strength of these bubbles.

A key property is density. A low-density EVA has larger, thinner-walled bubbles. It feels softer, but it is also weaker and tears more easily. A high-density EVA has very small, thick-walled bubbles. It feels much firmer and is far more durable.

The hardness, measured in "Asker C," is another key variable. You can have two foams with the same density, but different hardness levels. This is controlled by the specific chemical formulation of the EVA material itself.

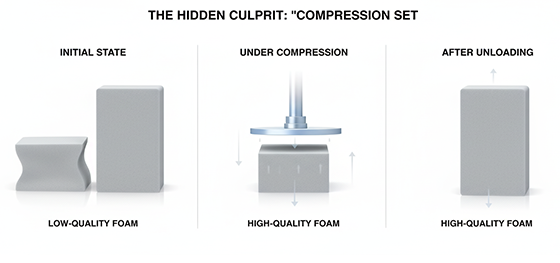

Now we come to the most important clue in our investigation. Why does foam lose its bounce? The technical term for this is "compression set."

Compression set is a measure of a material's memory. It tells you how well the material returns to its original shape after being squeezed for a long time.

A low-quality EVA has a high compression set. The walls of its tiny bubbles are weak. When you squeeze it, the bubbles pop or permanently deform. The foam stays squashed. The cushioning is lost forever. This is the "dead" feeling.

A high-quality EVA has a low compression set. Its bubbles are strong and resilient. You can squeeze it thousands of times, and it will bounce back to its original shape every time. It keeps its memory. This is the key to a long-lasting, reliable product.

Creating a high-quality EVA part is a precise industrial process. It is not just a simple foam. The process of eva foam injection molding gives a manufacturer a high degree of control.

The raw EVA material is mixed with a "blowing agent." This is a chemical that will release gas when heated. This mixture is then injected into a heated mold under immense pressure.

Inside the hot mold, the blowing agent activates. It creates the millions of tiny bubbles. The manufacturer has precise control over this process. By controlling the temperature, pressure, and the amount of blowing agent, they can precisely control the final density and hardness of the foam. This is a very different world from the low-pressure chemical reaction of pu injection moulding.

The verdict of our investigation is clear. The foam failed because the wrong type of EVA was chosen for the job.

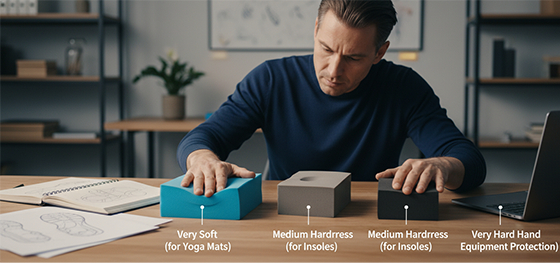

Choosing the right EVA is a critical design decision. You must think about the application.

For a yoga mat, you want a very soft, low-density EVA for comfort. Durability is less of a concern. For the midsole of a running shoe, you need a medium-density foam with excellent rebound and a low compression set to provide cushioning for thousands of impacts.

For a protective case insert, you need a high-density, firm EVA that will not tear and will hold the product securely for years.

This is where a knowledgeable manufacturing partner is essential. At JUCHENG, we can help you navigate these choices. We can provide samples of different densities and hardness levels. We can help you specify the right EVA with the right compression set. This ensures the part you get is not just a piece of foam, but a reliable, long-lasting solution.