ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

Your new industrial pump is assembled. All the bolts are tightened to the correct torque. You turn it on. And it leaks. A tiny, persistent drip from a flange connection.

The cause is almost always the same. The gasket. The small, seemingly simple piece of flexible plastic between the two hard metal faces has failed to do its one job.

This is a common failure, and it reveals a critical truth. Not all flexibility is created equal. Choosing the right flexible plastic sheet material is a science. It is about understanding the hidden properties that define a successful seal.

content:

The job of a gasket or a seal is simple. You squeeze it between two surfaces. It deforms and fills in all the microscopic gaps. This creates a barrier that stops liquid or gas from escaping.

The problem happens over time. The material is held under constant pressure. A bad material will slowly lose its "memory." It "forgets" its original shape. It becomes flat and hard.

Now, it is no longer pushing back against the metal faces. A microscopic gap opens up. The seal is broken. The leak begins. This failure is directly tied to a hidden material property.

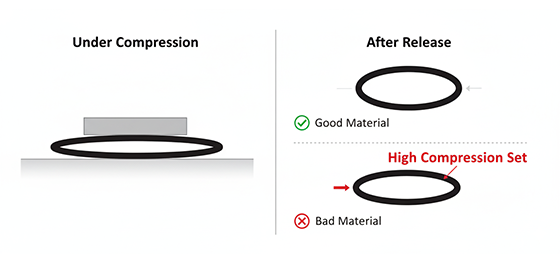

This is the most critical of all the properties of plastic for a sealing application. Compression set is a measure of a material's ability to return to its original thickness after being compressed for a long time.

A material with a "low" compression set is good. It has a great memory. It will spring back almost completely. This means it will continue to push against the sealing faces and maintain a tight seal for years.

A material with a "high" compression set is bad for sealing. It has a poor memory. It will stay permanently squashed. The pushing force is lost, and the seal will eventually fail. When you choose a flexible material for a gasket, its compression set rating is more important than almost any other number on the data sheet.

![]()

Several families of plastics are available as flexible sheets for gaskets and seals.

Silicone is a top performer. It has an excellent low compression set. And it can handle a very wide range of temperatures, from extreme cold to high heat. This makes it a great choice for many demanding jobs.

Elastomers like Neoprene, EPDM, and Viton are also fantastic choices. They offer different levels of chemical and oil resistance. EPDM is great for outdoor use in water. Viton is the champion for handling aggressive fuels and chemicals.

Thermoplastic materials like TPE and TPU are also used. They offer a good balance of flexibility, toughness, and cost. They can be a smart choice for less critical applications.

Even a material like Polypropylene (PP), if used as a very thin plastic sheet material, can be used for simple, non-critical seals or living hinges.

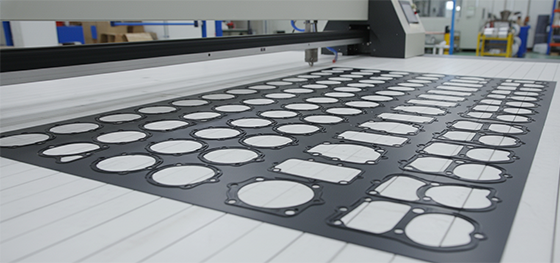

Once you have chosen your material, it needs to be cut into the final shape of your gasket. These are often complex shapes with precise bolt holes.

The traditional method is die-cutting. A sharp steel tool, like a cookie cutter, is made in the shape of your part. A press then uses this die to stamp the gaskets out of the sheet. This is very fast for high-volume production, but making the die is expensive and slow.

For prototyping and small-volume production, modern methods are much better. A digital knife cutter uses a computer-controlled blade to precisely cut any shape directly from the CAD file. It is like a plotter, but with a very sharp knife.

This "die-less" method is incredibly fast and flexible. We can cut one prototype or a hundred parts with no tooling cost. This allows you to test different gasket designs quickly and affordably.

Choosing the right flexible plastic sheet material is a critical engineering decision. You must consider the temperature it will see. The chemicals it will touch. And, most importantly, the amount of compression it must endure.

A cheap material with a high compression set is a guarantee of future failure. It is a leak waiting to happen.

This is a decision that requires expertise. A good manufacturing partner can be a vital resource. At JUCHENG, we can help you analyze your sealing application. We can review the material datasheets with you. We can help you select the material with the right balance of properties for your job.

This partnership ensures that your final seal is not just flexible. It is reliable. It is a solution you can trust.