ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

Your next product needs a "personality." Does it need to be flexible and forgiving, like a rubber gasket? Does it need to be unbreakably tough, like a power tool housing? Or does it need to be rigid and unflinching, like a support chassis?

The world of plastics offers you all these personalities. But to choose the right one, you must first learn how to ask the right questions. The language you need to speak is the language of the properties of plastic.

This guide is not a dictionary of scientific terms. It is a problem-solving handbook for designers and engineers. It starts with your need, and helps you find the property that meets it.

content:

Your Need: "I need a material that I can bend, roll, or hinge." The property you are looking for is flexibility. This is measured by a low flexural modulus.

For this, you would choose a flexible plastic sheet material like Polypropylene (PP) or LDPE. These materials can be bent thousands of times without breaking. This makes them perfect for living hinges on container lids.

Sometimes, you need flexibility simply because the part is very thin. A thin plastic sheet material made from a more rigid plastic, like PET or PVC, can still be very flexible. Think of a blister pack or a plastic folder. Here, the geometry (the thinness) is just as important as the material itself.

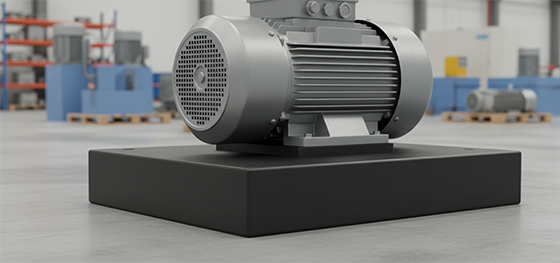

Your Need: "I need a material that will not bend or deform under load. It needs to be a solid foundation." The properties you are looking for are rigidity and hardness.

This calls for a hard plastic. But "hard" can mean two things. It can mean scratch resistance. Or it can mean stiffness (a high flexural modulus). Often, they go together.

Materials like Acrylic (PMMA) are very hard and scratch-resistant, but also brittle. For a part that needs to be truly robust, you would look for a rigid plastic sheet material. A great choice is a glass-fiber reinforced polymer, like GF-Nylon. The glass fibers act like a skeleton inside the plastic, making it incredibly stiff and strong. This is perfect for support brackets or structural housings.

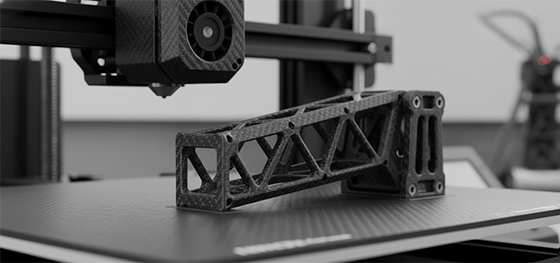

Your Need: "I need a part that can take a punch. It can be dropped or hit, and it will not shatter." The property you are looking for is toughness, or impact strength.

This is especially critical in 3D printing, where the layer-by-layer process can create weaknesses. To get a truly strong part, you need to choose the strongest 3d printer filament.

This often means a composite filament. These are special filaments made from a tough base plastic, like Nylon or PETG, that has been infused with chopped carbon fibers or glass fibers. These fibers bridge the layers and dramatically increase the final part's strength and stiffness. The result is a 3D printed part that can often rival the strength of machined aluminum, but at a fraction of the weight.

Your Need: "My part will operate in a very hot environment." The property you need is heat resistance. This is measured by the Heat Deflection Temperature (HDT).

Most common plastics will soften and deform at temperatures above 100°C. For a job that requires high heat, you need a specialist.

A heat resistant plastic material belongs to a family of high-performance polymers. Materials like PEEK, PEI (Ultem), and PPS are the champions here. They can withstand continuous operating temperatures of 150°C, 200°C, or even higher. This allows plastic parts to be used in demanding applications like engine components, medical sterilization trays, and industrial sensors.

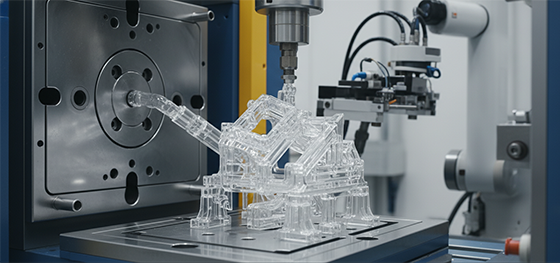

Your Need: "I need to create a very complex shape with high precision and repeatability." The property you are looking for is good moldability.

A good moldable plastic material, like ABS or Polycarbonate, has excellent flow characteristics when molten. It can fill every tiny feature of a complex injection mold. It also has predictable and low shrinkage as it cools. This allows a manufacturer to produce millions of identical parts with very tight tolerances.

A related property is the density plastic material. The density affects two things: the part's final weight and its cost. A lower density material will result in a lighter part. Since plastic is bought by weight, a lower density material can also sometimes lead to a lower cost per part. A designer must balance the need for a "solid" feel with the goal of light weight and low cost.

Your Need: "I want to make a product that is more sustainable and environmentally friendly." The property you are looking for is recyclability.

Many companies are now choosing to use a recycled plastic sheet material. These materials are made from post-consumer or post-industrial waste. For example, plastic bottles can be collected, cleaned, shredded, and melted down to create new sheets or pellets.

Using these materials can significantly reduce a product's carbon footprint. They can also have a unique aesthetic. A sheet made from recycled plastics often has small, colorful flecks from the original products, creating a one-of-a-kind finish. This is a powerful way to tell a story of sustainability with your product.