ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

When a product reaches the end of its life, where does it go? For decades, the answer for most plastic products was a landfill. A dead end.

But a new generation of designers, engineers, and consumers is asking a better question. Can the end be a new beginning?

This question is at the heart of a design revolution. And its most powerful tool is the recycled plastic sheet material. This is not just an "eco-friendly" alternative. It is a material with a unique story, a distinct beauty, and a powerful message.

content:

The concept is simple. It is called the circular economy. Instead of "take, make, and dispose," it is a loop. "Take, make, use, and remake."

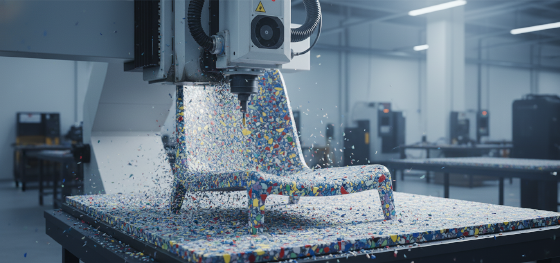

A recycled plastic sheet material is the physical embodiment of this idea. It is created by taking plastic waste, like single-use bottles or industrial scrap. This waste is cleaned, sorted, shredded into small flakes, and then heated and pressed into a new, solid, and usable sheet.

What was once considered trash is transformed into a valuable raw material. A dead end becomes a new beginning.

Unlike virgin plastics, which are perfectly uniform, recycled plastics have a unique personality. They have a history.

Often, the shredded flakes of old plastic are not perfectly uniform in color. When these flakes are melted and pressed together, they create a surface with a beautiful, random, terrazzo-like pattern. Every sheet is unique. There are no two alike.

This "perfect imperfection" has become a powerful tool for designers. They are not trying to hide the material's history. They are celebrating it.

You see this in modern furniture, where a tabletop made from recycled plastic becomes a unique piece of art. You see it in retail design, where a brand uses these unique panels to build its displays, sending a powerful message about its commitment to sustainability.

For a manufacturer, this uniqueness presents a challenge. We are used to working with perfectly uniform types of plastics. Recycled materials can be inconsistent.

The properties of a recycled plastic sheet material can vary slightly from batch to batch. Its density might not be perfectly uniform. It might contain tiny impurities.

Working with this material requires a different mindset. It requires experience and adaptability. A good manufacturer knows how to adjust their CNC machining parameters to handle these inconsistencies. They know which cutting tools work best. They understand how the material will behave.

The goal is to turn the material's inherent variability into a desirable feature, not a defect. This requires a close partnership between the designer and the manufacturer.

While the aesthetics are unique, recycled plastics are also serious engineering materials. The properties of plastic still apply.

A sheet made from recycled PET (rPET) will have many of the same properties as virgin PET. It will be stiff and strong. A sheet made from recycled HDPE (rHDPE) will be tough, durable, and chemical resistant, just like its virgin counterpart.

Engineers can look at the datasheet for a specific recycled plastic sheet and design with its properties in mind. It can be used for structural components, not just decorative ones.

The key is traceability. A reputable supplier of recycled sheets will provide data on the source of their material and its final, tested properties. This ensures that even when using a recycled material, you are not gambling with performance.

Ultimately, choosing to use a recycled plastic sheet material is more than just a technical decision. It is a marketing decision. It is a brand decision.

It gives your product a powerful story to tell. You are not just selling a chair. You are selling a chair made from 200 plastic bottles that were saved from the ocean. You are not just selling a display stand. You are selling your brand's commitment to a better future.

In a crowded market, a good story is a powerful differentiator. Consumers are increasingly choosing to support brands that align with their values.

By partnering with a manufacturer who is skilled in working with these materials, you can turn your next product into more than just an object. You can turn it into a statement.