ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-20 Origin: Site

What is the difference between a cheap-feeling product and a premium one? It is not always the price. It is not always the complexity. Often, it is simply the "feel."

The way a product feels in your hands. The sound it makes when you set it down. The quality of its surface. These small sensory details create a powerful, subconscious impression of quality.

Many designers believe you need expensive materials to create this feeling. But this is not true. A common, cost-effective material, when designed and manufactured with care, can feel more premium than any other. This is the hidden world of hdpe plastic material.

content:

The "feel" of a plastic part is a combination of several properties.

First is the texture. Is it a hard, glossy, and cold-feeling surface like ABS? Or is it a soft, matte, and warm-feeling surface?

Second is the density and weight. A thin, lightweight part can feel flimsy and cheap. A part with a thick, solid wall feels substantial and durable.

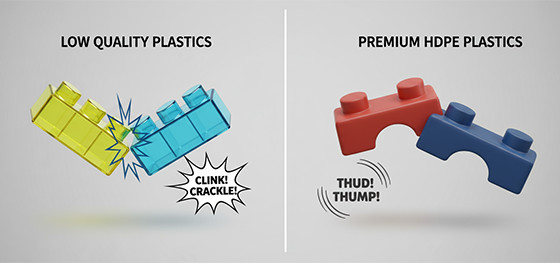

Third is the sound. What sound does the part make when you tap it or set it down? A high-pitched, hollow sound suggests cheapness. A low-pitched, solid "thud" suggests quality and density. Great designers think about all of these details.

Among the common types of plastics, High-Density Polyethylene, or HDPE, has a truly unique sensory profile.

Its surface is not hard and glossy. It has a naturally low-gloss, matte finish. It has a characteristic "waxy" feel. It is soft to the touch, but not squishy. This combination feels pleasant, understated, and honest.

It is also naturally translucent. This means light can pass through it, but it is diffused. This creates a soft, gentle glow, rather than a harsh transparency.

This is why many high-end, minimalist designers are choosing HDPE for their products. In its natural white or black state, it has a beautiful, stone-like quality. It does not try to look like something else. It is unapologetically plastic, but in a very elegant way.

The acoustic property of HDPE is another key advantage. Because it is a softer, denser plastic, it is very good at dampening sound and vibration.

When you tap on an HDPE part, you do not hear a sharp, high-pitched "click." You hear a dull, low-pitched "thump." This sound communicates solidity and quality.

This is very important in product design. Think about the lid of a high-end storage box. When you close it, you want to hear a quiet, satisfying "thud," not a loud, cheap "snap." By designing the box with a thick wall of HDPE, you can achieve this premium acoustic experience.

Beyond its sensory qualities, hdpe plastic material is also a champion of safety and durability.

It is a very pure polymer. It is BPA-free. Many grades are food-safe. This is why it is used for milk jugs and cutting boards. It is also very resistant to chemicals, so it will not degrade when cleaned with household cleaners.

HDPE is also incredibly tough and impact-resistant. Unlike harder, more brittle plastics, HDPE will not shatter or crack if you drop it. It tends to bend or dent, but not break.

This combination of non-toxic and shatter-proof makes it the gold standard for high-quality children's toys. It is safe for a child to use, and it can survive years of rough play.

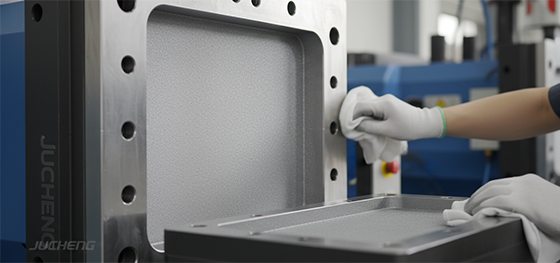

While HDPE is a cost-effective material, achieving a consistently beautiful finish requires a high level of manufacturing expertise.

The final surface finish of an injection-molded part is a direct copy of the mold's surface. To get that perfect, uniform matte texture on an HDPE part, the steel mold itself must be given a perfect texture.

At JUCHENG, we use processes like fine sandblasting or EDM texturing on our molds. This creates a precise, microscopic texture on the steel surface. When the molten HDPE is injected, it picks up this texture perfectly.

Controlling the injection process is also critical. The temperature and pressure must be perfect to avoid flow marks or gloss differences on the surface. This is the manufacturing skill that elevates a common material into a premium product.