ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

Should your design be limited by what a material can do? Or should your material be capable of bringing any design to life?

For centuries, designers were constrained by their materials. Wood could only be carved in certain ways. Metal could only be bent so far. But the invention of modern polymers changed everything.

It unleashed a new era of design freedom. This freedom is built on one key property: the ability of a material to flow like a liquid and capture the shape of any idea, no matter how complex. This is the magic of a great moldable plastic material.

content:

Look at the shape of a modern ergonomic mouse. Or the handle of a power drill. They are not made of simple, flat surfaces. They are made of complex, organic, three-dimensional curves.

These shapes are designed to fit perfectly in the human hand. They are the result of countless hours of user testing and refinement.

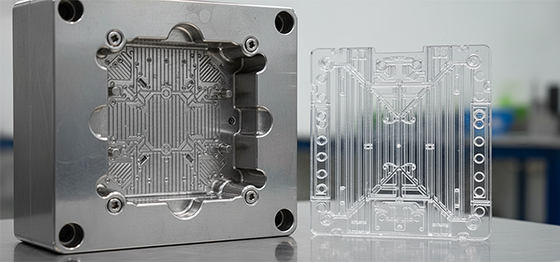

How is it possible to mass-produce such a complex shape with perfect consistency? The answer is injection molding. And injection molding is only possible because of the existence of a good moldable plastic material.

This property gives designers the freedom to create almost any shape they can imagine. It frees them from the constraints of traditional manufacturing.

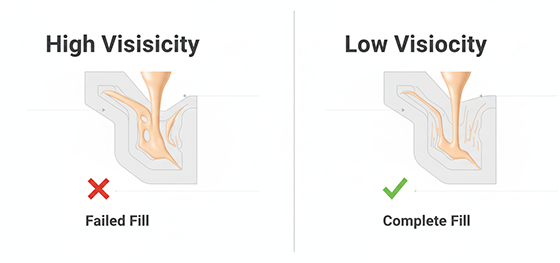

What makes a plastic "moldable"? The key scientific property is called "melt flow viscosity." It is a measure of how easily the plastic flows when it is melted.

A material with a low viscosity flows very easily, like water. A material with a high viscosity is thick and sluggish, like honey.

For injection molding, you generally want a material with a good melt flow. This allows the molten plastic to be injected under pressure and quickly fill every tiny corner, rib, and feature of a complex mold cavity.

A material with poor flow might fail to fill the thinnest sections of the mold. This leads to a defect called a "short shot." A good moldable plastic is a good-flowing plastic.

Different types of plastics have very different flow properties.

Materials like ABS, Polypropylene (PP), and Polystyrene have excellent moldability. They flow very easily. This is one of the reasons they are so popular for high-volume consumer products. They allow for fast cycle times and the creation of very thin-walled parts.

Materials like Polycarbonate (PC) can also be very moldable. This allows designers to create complex, crystal-clear parts with intricate optical features, like light pipes and lenses.

Even some high-performance plastics like glass-filled Nylon or PPS are designed to be a good moldable plastic material. This allows them to be formed into complex, strong, and heat-resistant parts for automotive and industrial applications.

But a good flow can also be a source of problems if it is not properly understood and controlled.

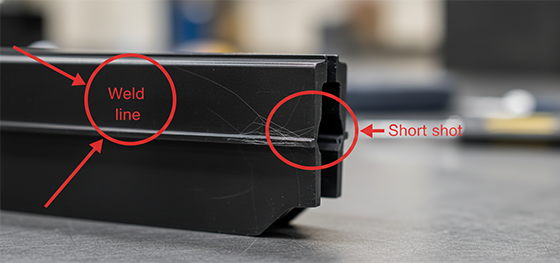

When molten plastic flows into a mold from multiple entry points, or flows around an obstacle like a core pin, the different flow fronts must meet and fuse together. The line where they meet is called a "weld line."

If the plastic has cooled down too much by the time these fronts meet, they will not fuse together perfectly. This creates a weak spot in the part. It can also be a very ugly cosmetic flaw.

Another problem is "flash." If the plastic flows too easily and the mold is not clamped with enough force, the molten plastic can escape from the mold cavity through tiny gaps. This creates thin, unwanted flaps of plastic on the finished part.

Controlling these issues is the art of injection molding.

How do we prevent these problems and harness the full potential of a material's moldability? We use a combination of experience and science.

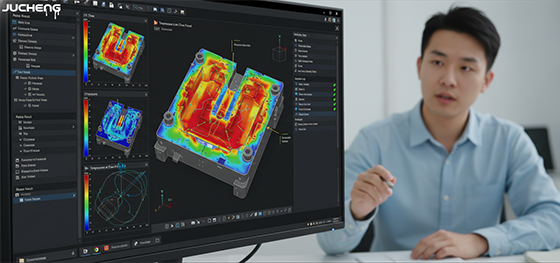

This is where a true manufacturing partner adds huge value. Before we ever build a mold, our engineers use a powerful tool called Moldflow Analysis software.

This software allows us to simulate the entire injection molding process on a computer. We can see exactly how your chosen moldable plastic material will flow into every part of your design. We can predict where weld lines will form. We can see where air might get trapped.

This allows us to optimize the design of the part and the mold before any steel is cut. We can adjust the gate locations. We can change wall thicknesses. We can solve problems before they happen. This DFM partnership is the secret to turning your most ambitious design into a flawless, repeatable, and cost-effective product.