ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

What is the most important element in a room? Is it the furniture? The color of the walls? For many great designers, the answer is simpler. It is light.

How light enters a space, how it is shaped, and how it is diffused defines our entire perception of that space. It creates mood. It directs our attention. It transforms the ordinary into the beautiful.

And one of the most powerful and versatile tools for a designer to control light is the humble thin plastic sheet material. It is not just a barrier. It is a canvas for sculpting light itself.

content:

When you think of a thin sheet of plastic, you might think of a simple report cover or a flimsy package. But in the hands of an architect or a product designer, it becomes a powerful tool.

It can become a massive, backlit wall in a modern office, creating a soft, ambient glow. It can become the elegant, curved diffuser on a high-end LED lamp, turning a harsh point of light into a gentle, inviting pool of illumination.

It can also be used to obscure and create privacy. A frosted plastic sheet in a partition allows light to pass through, keeping the space bright, but obscures the details on the other side. The material becomes a manager of light and information.

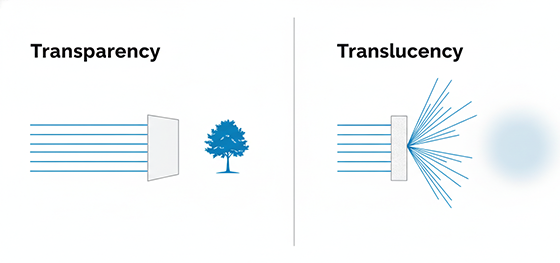

To use thin plastics effectively, you must understand the language of light. The two most important words are transparent and translucent.

A transparent material allows light to pass through with very little scattering. You can see clearly through it, like a window. It is about clarity and direct vision.

A translucent material also allows light to pass through, but it scatters it in many different directions. You cannot see clearly through it. This is the property of "diffusion." The light that comes out is soft, even, and gentle.

Most applications of thin plastic sheet material in design are not about transparency. They are about mastering the art of translucency to create a specific mood or to solve a visual problem.

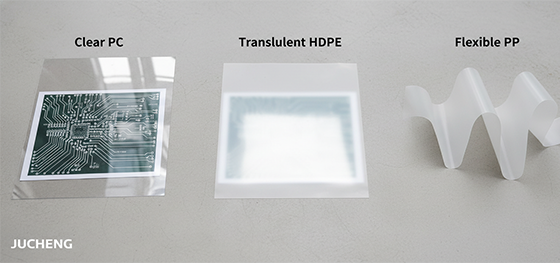

Designers have a wide palette of materials to choose from, each with its own unique optical properties of plastic.

Polycarbonate (PC) is the champion of transparent sheets. It is crystal clear, like glass, but it is also incredibly impact-resistant. This makes it perfect for safety guards and durable windows.

Acrylic (PMMA) is another beautifully clear material. It is more scratch-resistant than PC, but also more brittle. Its real strength is its ability to be "edge-lit." Light can travel through the sheet and make the edges glow, creating stunning visual effects.

Polypropylene (PP) is a naturally translucent material. It has a milky, cloudy appearance that makes it a fantastic and cost-effective light diffuser. It is also very flexible, so it can be used to create curved lampshades.

Specialty diffusing sheets are also available. These are often made from PC or PMMA, but with special diffusing particles added to them. This allows a designer to precisely control the amount of diffusion and light transmission.

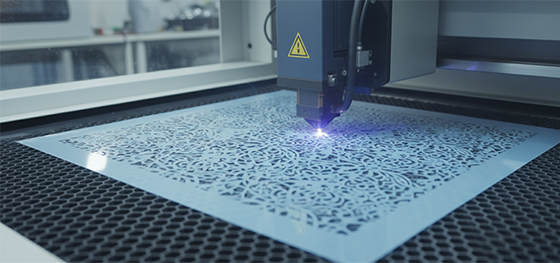

A thin plastic sheet material can be difficult to work with. It can be flimsy and hard to hold. If not handled correctly, it can be easily scratched or damaged.

Cutting these materials requires precision. For creating complex shapes, a laser cutter is the best tool. It can cut intricate patterns with a clean, polished edge, and it does not put any mechanical stress on the material.

Bending thin sheets also requires special techniques. A process called "heat bending" or "line bending" uses a heated wire to soften a precise line on the plastic. The sheet can then be cleanly folded along that line to create a sharp corner.

A manufacturing partner with experience in these techniques is essential. They need the right equipment and the right touch to turn a delicate sheet into a precise, finished part.

For a designer, creating the perfect lighting effect is a process of trial and error. You need to see how a material interacts with your specific light source.

This is where prototyping is critical. A manufacturer can quickly fabricate several different diffuser prototypes for you from different materials. Or with different levels of diffusion.

You can then test these prototypes with your actual product. This allows you to make an informed, real-world decision. It is the only way to ensure that the final product perfectly matches your creative vision.

Working with a partner who understands this creative process is key. At JUCHENG, we can be your partner in sculpting light. We can provide the materials and the manufacturing expertise to help you bring your vision to life.