ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-20 Origin: Site

The simulation was perfect. Your Finite Element Analysis (FEA) showed that the new machine guard, made from clear PET plastic, could easily withstand the expected impacts. The design was approved.

The first prototype arrives. It looks beautiful. It is crystal clear and rigid. You install it on the machine. A technician accidentally drops a small wrench. It hits the guard. The entire panel shatters.

What went wrong? The simulation said it was strong enough. This is a classic engineering mystery. And its solution lies in a hidden "personality flaw" of pet plastic material.

content:

Polyethylene terephthalate, or PET, is one of the most common types of plastics on Earth. It is famous for being the material of disposable water and soda bottles.

It has many attractive properties for engineers. It is very strong. It is very rigid. It has excellent dimensional stability. And, of course, it can be crystal clear. This makes it seem like a perfect, low-cost alternative to polycarbonate for applications like transparent covers and guards.

But it has a secret weakness. A fatal flaw, if you do not know how to design for it. This weakness is called "notch sensitivity."

To understand notch sensitivity, think of tearing a piece of paper. Tearing a fresh edge is difficult. But if you make a tiny cut on the edge first, the paper tears easily from that point. That tiny cut is a "notch."

PET behaves in a similar way. The material itself is very tough. It can absorb a lot of energy. But if there is a tiny, sharp point of stress concentration—a notch—it becomes surprisingly brittle. An impact will cause a crack to start at that notch and travel through the material catastrophically.

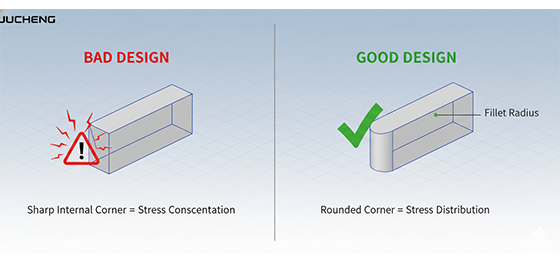

So, where was the "notch" in our shattered machine guard? It was not a visible cut. It was a design feature. The guard had sharp, 90-degree internal corners where it was mounted to the machine frame.

In an FEA simulation, this sharp corner might look fine. But in the real world, it is a massive stress concentrator. It is a microscopic "notch" waiting for an impact. When the wrench hit the panel, all the impact energy focused on that sharp corner, and the part shattered.

How do we solve this? The solution is surprisingly simple. We eliminate the notches.

In plastic part design, the secret weapon against stress concentration is the "fillet," or a rounded internal corner.

By adding a smooth, generous radius to all internal corners, you allow the impact energy to spread out over a larger area. There is no single sharp point for a crack to start. This simple design change can dramatically increase the real-world impact strength of a pet plastic material part.

This is a perfect example of why Design for Manufacturability (DFM) is so important. A good manufacturing partner would have spotted those sharp corners in the design phase. They would have warned you about the notch sensitivity of PET and recommended adding fillets. This expert advice prevents the failure before it ever happens.

While we have focused on its weakness, it is important to remember PET's strengths. Its most famous application is in packaging. But the same polymer is also known by another name: Polyester.

When PET is melted and extruded into a thin filament, it becomes the strong, flexible fiber used to make a huge percentage of the world's clothing, ropes, and sails.

This shows that the material itself is inherently tough. Its final properties—brittle or tough—depend entirely on its form and how it is processed. This dual personality is what makes understanding the material so critical.

So, is pet plastic material a good choice for your engineering project?

The answer is yes, absolutely. If you need excellent clarity, high rigidity, and good dimensional stability at a low cost, it is a fantastic option.

But you must respect its personality. You must design for its notch sensitivity. You must be generous with your radii and fillets. You must avoid sharp corners.

This is where collaboration with your manufacturing partner is key. At JUCHENG, our DFM review process is designed to catch exactly these kinds of issues. We can help you turn a potentially brittle design into a robust and reliable part. We help you unlock the full potential of this common, but powerful, material.