ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-22 Origin: Site

What if a single material could be a rock-hard structural component, a tough and flexible bumper, and a soft, cushiony foam? It sounds like science fiction. But it is not.

This is the incredible versatility of polyurethane. It is the undisputed star of the reaction injection molding (RIM) world. It is a chameleon. A material with a thousand different faces.

Understanding the possibilities of polyurethane reaction injection molding is not just about understanding a material. It is about unlocking a new level of design freedom. This guide will introduce you to its many personalities.

content:

When an engineer says "polyurethane," they could be talking about a huge range of materials.

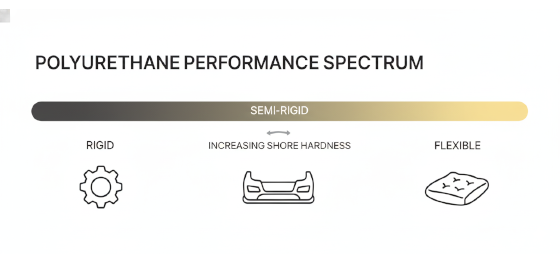

On one end of the spectrum, you have extremely soft and flexible polyurethane elastomers. These feel like a tough rubber. On the other end, you have highly rigid and solid polyurethanes. These behave like a standard engineering plastic, like ABS.

And in between, there is a whole universe of possibilities. Semi-rigid materials. Materials with different levels of impact resistance. Materials with different textures. And even foams. This incredible range is what makes polyurethane the primary choice for the versatile reaction injection molding process.

How is this versatility possible? The secret is in the chemistry.

All polyurethanes are created by reacting two liquid components: a polyol and an isocyanate. But these are not single chemicals. They are families of chemicals.

By carefully choosing a specific type of polyol and a specific type of isocyanate, and by mixing them in a precise ratio, a chemist can "dial in" the final properties of the plastic. It is like a master chef creating a sauce. A little more of this, a little less of that, and the entire character of the final dish changes.

This is why it is called a "formulation." Each formulation is a unique recipe, designed for a specific job.

One of the most popular roles for polyurethane reaction injection molding is to create tough, solid, rubber-like parts. These are called elastomers.

These formulations are designed for maximum impact resistance and durability. They can be bent, stretched, and compressed, and they will always return to their original shape.

This makes them the perfect choice for parts that need to be "tough as nails." Think of the large, flexible bumpers on a city bus. Or the rugged fenders on a piece of agricultural equipment. These parts are constantly getting hit, scraped, and abused. A rigid plastic would shatter. But a polyurethane elastomer just shrugs off the damage.

The other major role for polyurethane is completely different. By adding a "blowing agent" to the chemical recipe, we can create a structural foam.

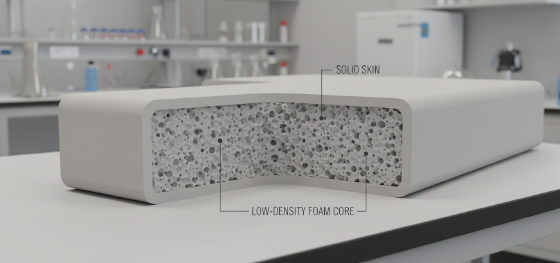

As the chemical reaction happens in the mold, the blowing agent releases a gas. This creates millions of tiny, uniform bubbles within the material. The material expands to fill the mold.

The result is a part with a "sandwich" structure. It has a solid, dense outer skin where it touched the cold mold. And it has a lighter, less dense foam core.

This is a brilliant engineering trick. It is the same principle used in an I-beam. The structure is incredibly stiff and strong for its weight. This makes it perfect for large, lightweight, structural parts. Think of the large housing for a medical imaging machine or a panel on a piece of construction equipment.

So, which polyurethane personality is right for your project?

Do you need a part that can absorb impacts and survive a tough life? You need a solid elastomer. Do you need a huge part that is as light and stiff as possible? You need a structural foam. Do you need a rigid housing with a beautiful surface finish? You need a solid, rigid polyurethane.

This is a critical decision that goes beyond just the part's geometry. It is about defining the part's character.

A good manufacturing partner like JUCHENG has deep expertise in these different formulations. We can help you navigate the huge world of polyurethane reaction injection molding. We can provide samples. We can offer advice. We can help you choose the perfect material to bring your product's unique personality to life.