ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-21 Origin: Site

Pick up a cheap toy. Now pick up a high-end remote control. What is one of the first things you notice? The weight.

One feels hollow, light, and insignificant. The other feels solid, substantial, and valuable. This feeling is not an accident. It is a deliberate design choice. It is the result of carefully selecting a density plastic material.

Density is one of the most underrated properties of plastic. It is not just a number on a data sheet. It is a powerful tool for shaping your customer's perception of quality. This guide is about how to use this tool wisely.

content:

In many areas of engineering, light weight is the ultimate goal. But in consumer products, this is not always true. For a handheld object, a certain amount of "heft" is directly linked to our perception of quality and durability.

A product that feels too light can feel cheap or flimsy, even if it is very strong. A product with a satisfying weight feels robust and well-made.

Great product designers understand this. They deliberately choose a density plastic material that gives their product the right feel. Sometimes, they even add internal metal weights to a plastic product to achieve this premium sensation. Weight is a key part of the user experience.

So, what is density? It is a very simple measure of how much "stuff" is packed into a certain amount of space. Its scientific definition is mass per unit volume.

On a material datasheet, you will see it listed as "Specific Gravity" or in units like g/cm³. Water has a specific gravity of 1.0. Plastics with a density less than 1.0 will float. Plastics with a density greater than 1.0 will sink.

For example, Polypropylene (PP) is a very lightweight plastic, with a density of around 0.9 g/cm³. It floats. On the other hand, a high-performance, glass-filled plastic like PEEK can have a density of 1.4 g/cm³ or more. It feels much heavier and more substantial. This number is the starting point for your design decision.

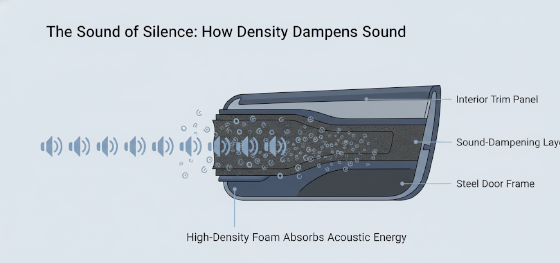

Density does more than just add weight. It also has a huge impact on a product's acoustic properties.

Low-density, thin-walled parts tend to vibrate easily. They can rattle and produce high-pitched, hollow sounds that we associate with cheapness.

Higher-density materials are much better at dampening, or absorbing, sound and vibration. When you close the door of a luxury car, you hear a quiet, solid "thump." This is because the door panels are made from and lined with high-density materials designed to absorb noise.

The same principle applies to your product. A smart speaker with a housing made from a dense, thick-walled plastic will have better sound quality. It will have less unwanted vibration and resonance. The choice of density plastic material directly affects the audio performance.

While a higher density can create a feeling of quality, it also has a direct impact on cost. And not always in the way you might think.

Plastic raw material is purchased by weight. In kilograms or pounds.

Imagine you are making one million small plastic caps. If you choose a low-density plastic like PP instead of a higher-density plastic like ABS, each cap will weigh less. Over a million parts, this can add up to a huge saving in the total amount of raw material you need to buy.

This is the engineer's trade-off. You must balance the desired "premium feel" from a higher density with the potential cost savings of a lower density material.

So, what is the right density for your product? There is no single answer. It is about finding the sweet spot for your specific application.

You must consider your brand's positioning. Are you a luxury brand where a substantial feel is a key feature? You must consider your product's function. Is it a portable device where light weight is critical? You must consider your budget. How important is minimizing the cost per part?

This is a decision that requires both data and feel. This is where prototyping with a knowledgeable partner is invaluable. At JUCHENG, we can help you prototype your part in a few different materials.

We can make one version in a lighter PP and another in a heavier ABS. This allows you to hold them in your hand. You can feel the difference. You can hear the difference. This real-world experience is the only way to make the right final choice. It is how we help you turn a number on a datasheet into a product that feels just right.