ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 3 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

You have a project. You need 50 high-quality prototypes. You get a quote. But what does that number on the quote actually mean? Is it a good value? Where is your money really going?

Understanding the vacuum casting cost is not just about budgeting. It is about making smart investment decisions. It is about understanding the relationship between cost, quality, and the value you get in return.

This guide will deconstruct that quote for you. We will pull back the curtain on how the price is calculated. This will empower you to manage your budget and maximize the value of your next project.

content:

A professional quote for a Vacuum Casting project is typically broken down into three main parts. Understanding these parts is the first step to understanding the total cost.

The first is the one-time cost of the Master Pattern. This is the perfect original model of your part.

The second is the one-time cost of the Silicone Mold. This is the tool that will be used to create all your copies.

The third is the per-part cost. This is the cost of the liquid resin material and the labor required to cast and finish each individual copy. Your total project cost will be (Master Cost + Mold Cost) + (Per-Part Cost x Quantity).

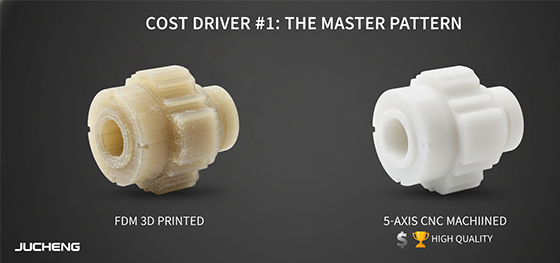

The master pattern is your initial investment in quality. Its cost depends on how it is made.

A master made with a simple FDM 3D printer will be cheap. But it will have layer lines and a rough surface. This means a technician will have to spend many hours hand-sanding and finishing it to perfection. This labor can be very expensive.

A master made with a high-end process like SLA 3D printing or 5-axis CNC machining will have a higher upfront machine cost. But it will come out with a near-perfect surface. This means it requires much less hand finishing.

Often, investing in a higher quality master pattern is the smarter choice. It leads to a better final result and can sometimes even be cheaper overall when you factor in the reduced labor costs.

![]()

The size and complexity of your part affect both the silicone mold cost and the per-part cost.

The silicone mold cost is directly related to how much liquid silicone rubber is needed to make it. A large, thick part will require a much larger and thicker mold than a small, simple part. Silicone rubber is an expensive material, so this can be a significant cost driver.

The per-part cost is also affected by size. A larger part simply uses more polyurethane resin, which increases the material cost for each copy.

Complexity also adds to the per-part labor cost. A part with many delicate features is harder to demold without breaking. A part that requires complex painting or assembly will take more technician time for each copy.

The final major driver of the vacuum casting cost is your choice of material. Not all polyurethane resins are priced the same.

A general-purpose, ABS-like opaque resin is the most common and cost-effective choice.

Specialty resins cost more. A water-clear, UV-stable resin that mimics polycarbonate is a more expensive formulation. A soft, rubber-like elastomeric resin also has a higher cost.

At the top of the price list are certified materials. For example, a resin that is certified as biocompatible for medical devices, or a resin that has a UL94-V0 flame retardant rating, will be the most expensive. You are paying for the advanced chemistry and the cost of certification.

Understanding these cost drivers empowers you to make smart decisions.

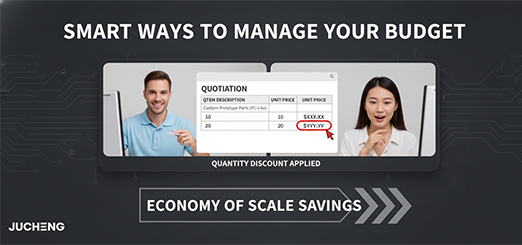

First, talk to your manufacturing partner about quantity. A silicone mold can make about 20 copies. If you need 50 copies, the provider will need to make three molds. The cost of these extra molds will be in your quote. Because the master pattern cost is a one-time setup, the cost per part will go down as you order more copies.

Second, consider your finish. If you can test an early prototype without paint, you can save money. You can then choose to paint only the final batch of parts that you will show to customers.

Finally, have an open conversation with your partner. At JUCHENG, we believe in transparent pricing. We can walk you through your quote. We can explain every cost. We can also provide DFM feedback to help you simplify your design for more cost-effective manufacturing. This partnership is the best way to ensure you get the maximum value for your investment.