ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-28 Origin: Site

Your design is finalized. Your engineering tests are complete. You are ready for the market. There is just one problem. The steel injection mold for mass production will take 12 weeks to build.

Twelve weeks. In today's market, that is an eternity. It is a huge, risky gap in your project timeline. Your sales team has nothing to show. Your marketing team cannot start. Your competitors get a 3-month head start.

What if you could build a bridge across that gap? A way to get hundreds of production-quality parts in your hands in just a couple of weeks? This is the strategic power of Vacuum Casting. It is not just another prototyping method; it is a business strategy.

content:

The leap from a final prototype to the first production run is often called the "valley of death" in product development. This is the period where your product is real in theory, but you have no physical units to move the business forward.

The main cause of this delay is the lead time for hard tooling. A production-grade injection mold is a complex piece of steel engineering. It needs to be designed, machined, polished, and tested. This process is long and expensive. A typical lead time of 8 to 16 weeks is normal.

During this time, your project is stalled. You cannot conduct beta testing with real customers. You cannot get the product into the hands of your sales force. You cannot begin the certification process. This delay is not just frustrating; it is a significant business risk.

This is where Vacuum Casting shines as a strategic tool. It is not just for making a handful of prototypes. It is a form of "bridge manufacturing." It is designed to produce low to mid-volumes of production-quality parts, bridging the gap while you wait for your hard tooling.

Imagine being able to get 100 perfect units of your new product just two weeks after finalizing the design. This changes everything.

Your marketing team can conduct a photoshoot and start building their campaigns. Your sales team can visit key clients and secure pre-orders. Your engineering team can perform extensive real-world testing. You can even launch your product in a limited market to gain early traction.

This is the core value of a professional vacuum casting service. It is a tool that buys you time and reduces your market risk.

How can this process be so much faster than injection molding? The magic lies in the tooling. Instead of a hard steel mold, vacuum casting uses a soft, flexible silicone mold. The vacuum casting process is a masterpiece of skilled craftsmanship.

It all begins with a flawless master pattern. This is a perfect, high-resolution model of your final part. The quality of this master pattern is everything. At JUCHENG, we use our advanced 5-axis CNC machines or high-resolution SLA 3D printers to create master patterns with a perfect, class-A surface finish.

This master pattern is then suspended in a casting box. Liquid silicone rubber is poured around it and cured in an oven. The cured silicone block is then carefully cut open, and the master pattern is removed. This leaves a soft, flexible mold with a perfect, detailed cavity inside. This entire mold-making process takes only a couple of days.

To make a part, the two liquid components of a polyurethane resin are mixed. The silicone mold is placed in a vacuum chamber. The resin is then poured into the mold under a powerful vacuum. This is the "vacuum" in vacuum casting. It is a critical step that sucks every last air bubble out of the resin, ensuring a perfectly solid, bubble-free part. The resin then cures in the mold, and the finished part is removed.

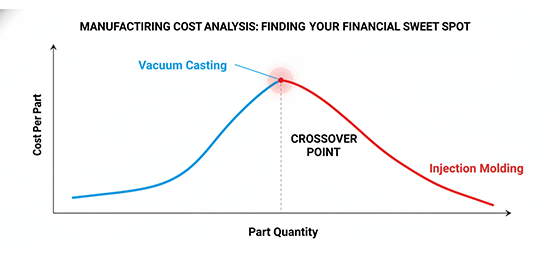

This strategy sounds great, but when does it make financial sense? Understanding the vacuum casting cost structure is key.

The cost model is the inverse of injection molding. For injection molding, the upfront tooling cost is massive, but the cost per part is very low. For vacuum casting, the upfront tooling cost (the master pattern and silicone mold) is very low, but the cost per part is higher because it is a more manual process.

This creates a "break-even point." For production quantities below this point, vacuum casting is the cheaper overall solution. Above this point, the high volume makes injection molding more economical.

Where is this sweet spot? It depends on the size and complexity of your part. But generally, for quantities ranging from 10 to about 500 pieces, vacuum casting offers an unbeatable combination of speed and cost-effectiveness. It is the perfect financial tool for bridge manufacturing.

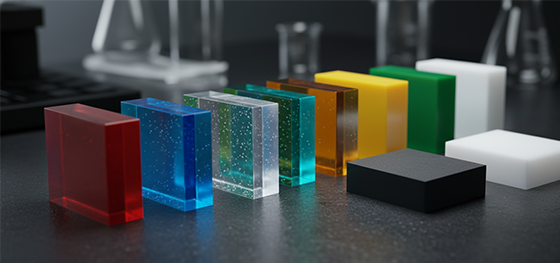

A key advantage of vacuum casting is the huge range of available materials. The vacuum casting materials are typically two-part polyurethane resins. These resins can be formulated to mimic the properties of almost any production plastic.

You can choose a rigid, white resin that perfectly simulates the look and feel of ABS. You can choose a crystal-clear resin that mimics polycarbonate or acrylic. You can choose a tough, black resin that behaves like Nylon.

You can also choose from a wide spectrum of rubber-like elastomers. These can have a hardness ranging from a very soft, gel-like feel (Shore 20A) to a firm, tough rubber feel (Shore 90A).

These resins can also be custom-colored to perfectly match your brand's specific Pantone color. This means the parts you get are not just functional equivalents; they are cosmetic duplicates of your final product.

Vacuum casting is a process that is part science, part art. The final quality is highly dependent on the skill of the technicians and the quality of the equipment.

When choosing a vacuum casting service, you are choosing a partner. You need a partner with deep expertise. A partner who can create a flawless master pattern. A partner who understands the art of making a perfect, bubble-free silicone mold. A partner who can guide you to the right material choice.

At JUCHENG, this is the level of partnership we provide. We see vacuum casting not just as a way to make a part, but as a strategic tool to help you launch your product faster and with less risk. We are here to help you build that bridge to success.

content is empty!