ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 3 Author: Allen Xiao Publish Time: 2025-11-28 Origin: Site

Your startup has a brilliant new product. You need 50 perfect units for a critical investor demo next month. You search online for a vacuum casting service and get a dozen quotes. One is significantly cheaper than the others. Should you take it?

This is a dangerous moment. Choosing the wrong partner can be a disaster. You might receive parts that are full of bubbles, warped, or have a terrible surface finish. Your demo is ruined. Your project is delayed.

A professional Vacuum Casting service delivers more than just a low price. It delivers certainty. This guide will show you how to tell the difference.

content:

Anyone can buy a small vacuum chamber and call themselves a casting service. A professional operation is a different world.

A professional service has a clean, organized, and climate-controlled workshop. The materials used in vacuum casting are very sensitive to temperature and humidity. A controlled environment is the first sign of quality.

They use large, commercial-grade vacuum casting machines. These machines can pull a more powerful and more consistent vacuum. This is critical for producing bubble-free parts. They will also have dedicated, temperature-controlled ovens for curing the silicone molds and the cast parts.

A simple shop might be using homemade equipment in a garage. The difference in the final part quality will be huge.

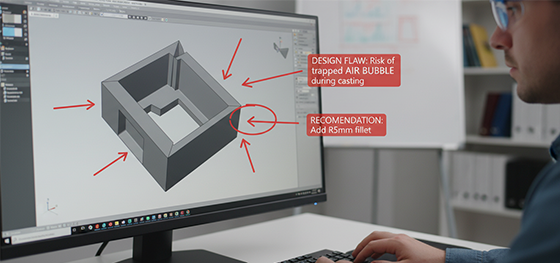

The most important service a good partner provides happens before any work begins. This is the expert review of your design.

A cheap vendor will just take your file and give you a price. A true professional service will have their engineers analyze your part for manufacturability (DFM).

They will look for potential problems. "This sharp internal corner is going to trap air bubbles. We recommend adding a small fillet here." "This thin wall might be difficult to fill. Let's discuss the gate location."

This DFM feedback is incredibly valuable. It is a free engineering consultation that prevents problems before they happen. It shows that the company is thinking about your success, not just their invoice. This is a clear sign you are working with a top-tier vacuum casting service.

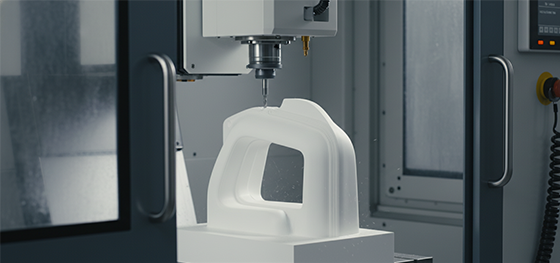

The quality of a vacuum cast part can never be better than the quality of the master pattern. The silicone mold is a perfect copy of the master. Every tiny flaw will be transferred.

A cheap service might use a low-resolution FDM 3D printer to make the master. The final parts will have visible layer lines and a poor surface finish.

A professional service, like JUCHENG, understands this. We treat the master pattern as the most critical component. We use our best technologies to create it. For complex shapes, we use high-resolution SLA 3D printing. For the ultimate in precision and surface finish, we use our 5-axis CNC machines.

After machining, the master pattern is then hand-finished by skilled craftsmen. It is sanded and polished to a flawless, Class-A surface. This obsession with the master pattern is the secret to a beautiful final part.

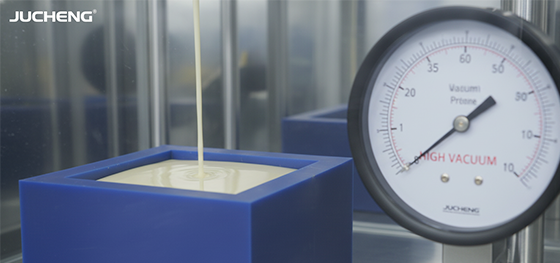

The actual casting process is where a service's attention to detail is truly tested.

The biggest enemy is air bubbles. They can get trapped in the resin during mixing, or in the mold during pouring. A professional service uses a powerful vacuum to "de-gas" the mixed resin before it is poured. Then, the pouring itself happens inside the vacuum chamber. This is the only way to guarantee a bubble-free part.

Curing is also critical. The cast part must be cured at a precise, stable temperature for a specific amount of time. This ensures the material reaches its full strength and dimensional stability. A professional service uses calibrated ovens for this. A cheap shop might just leave it on a shelf to "air cure," which results in a weak and inconsistent part.

A vacuum casting service is more than a transaction. It is a partnership built on trust and expertise.

When you are evaluating potential partners, look beyond the price. Ask about their DFM process. Ask how they make their master patterns. Ask about their vacuum and curing equipment. Ask to see examples of their work.

Choosing a partner with a deep commitment to quality and process control is the best way to protect your project. It is your guarantee that the parts you receive will be perfect, on time, and ready to impress your investors.