ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-28 Origin: Site

As a designer, it feels like magic. You spend weeks perfecting a 3D model on your computer. You send the file to a manufacturing partner. A short time later, a box arrives with 20 perfect, physical copies of your design.

The surface finish is flawless. The details are crisp. They feel like final products. How is this possible in such a short time and without expensive tooling?

The answer lies in a beautiful and skilled manufacturing method. It is time to look inside the vacuum casting process. It is a journey from a single original to many perfect copies.

content:

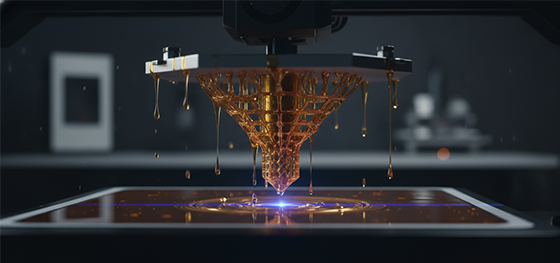

The entire Vacuum Casting process is based on creating copies. Therefore, the quality of the copies can never be better than the quality of the original. This original is called the "master pattern."

Creating a perfect master pattern is the first and most critical step. This master is a perfect physical representation of your CAD file. Its surface must be flawless.

At a professional service provider like JUCHENG, we use our best technologies for this. For parts with very complex geometries, we often use high-resolution SLA 3D printing. For parts that require ultimate precision and a glass-smooth surface, we use our 5-axis CNC machines.

After the master is made, it is then handed to a skilled craftsman. They will spend hours sanding, polishing, and perfecting its surface until it is absolutely flawless. This obsession with the master is the foundation of the entire process.

![]()

The next step is to create the heart of the process: the silicone mold.

The perfect master pattern is carefully prepared. Parting lines are defined. Gates and vents are planned. It is then suspended in the middle of a casting box.

Liquid silicone rubber, which has the consistency of honey, is then mixed and poured into the box, completely surrounding the master pattern. The entire box is placed under a vacuum to remove any air bubbles from the liquid silicone.

The box is then moved to a curing oven. The silicone is baked at a stable temperature for many hours. This cures the liquid rubber into a solid, flexible block. This soft mold is now ready to become the mother of many copies.

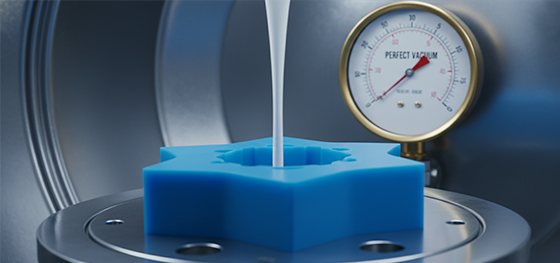

This is the step that gives the vacuum casting process its name. It is the most critical moment for ensuring a perfect part.

The silicone mold is placed inside a vacuum chamber. In a separate cup, the two liquid components of the polyurethane casting resin are mixed. This mixed resin is also placed inside the chamber.

The door is sealed, and a powerful pump removes almost all the air from the chamber. This is essential. It pulls any microscopic air bubbles out of the mixed resin.

Then, while still under vacuum, the technician tilts the cup and pours the bubble-free resin into the mold. The liquid flows smoothly into every tiny detail of the mold cavity. Because there is no air, there is no chance of air getting trapped and creating a void or a surface bubble.

![]()

Once the mold is filled, the vacuum is released. The mold is removed from the chamber and placed into another oven.

The heat accelerates the curing of the polyurethane resin. In as little as 30 minutes, the liquid resin transforms into a solid, stable plastic part.

Now comes the moment of birth. The technician takes the cured mold. They carefully cut it open along the pre-planned parting line. The soft, flexible silicone is then peeled back to reveal the perfect, solid copy inside.

This demolding process is gentle. Because the mold is soft, it can be used to create parts with complex features and even some undercuts without damage.

The magic of the vacuum casting process is that this can now be repeated.

The silicone mold is reassembled. It is placed back in the vacuum chamber. And another perfect copy is cast.

A single silicone mold can typically produce around 15 to 25 copies before it starts to degrade. This is what makes vacuum casting a "short-run production" process.

It is this combination of skilled craftsmanship and controlled science that allows a single digital file to be transformed into a small batch of beautiful, production-quality parts in just a matter of days.