ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 3 Author: Allen Xiao Publish Time: 2025-11-28 Origin: Site

Your prototype needs to do more than just look right. It needs to feel right. When an investor or a potential customer holds it in their hands, it must feel like the real, final product.

But the Vacuum Casting process does not use the same plastics as mass production. It uses a family of materials called polyurethane resins. So how do you bridge this gap? How do you make a polyurethane part feel exactly like your final ABS or Polycarbonate product?

This is the art and science of choosing the right vacuum casting materials. It is a process of expert mimicry.

content:

The "feel" of a plastic part is a complex combination of properties. It is the hardness of the surface. It is the stiffness of the part when you try to bend it. It is the weight in your hand. It is the texture.

Your final product will be made from a specific production plastic, for example, ABS. Your prototype must replicate these sensory inputs as closely as possible to be a useful tool for market testing or user feedback.

A prototype that looks right but feels wrong can give you misleading feedback. This is the challenge that a good selection of vacuum casting materials is designed to solve.

Polyurethane resins are the chameleons of the polymer world. They are a family of two-part liquid plastics that can be formulated to achieve a vast range of properties.

By changing the specific chemistry of the "A" and "B" components, material scientists can create resins that are hard and rigid, or soft and flexible. They can be crystal clear or completely opaque. They can be fast-curing or slow-curing.

A professional vacuum casting service maintains a library of these different formulations. Each one is a tool in their toolkit, ready to be chosen to perfectly mimic the properties of a specific production plastic.

This is the most common requirement. A designer needs a prototype that feels just like their final, injection-molded ABS part.

For this, we use a family of "ABS-like" polyurethane resins. These formulations are designed to have a very similar hardness, stiffness, and impact strength to standard ABS.

These resins are naturally an off-white or yellowish color. But they can be pigmented to match any custom color, including the specific white or grey of a medical device.

When cast in a mold with a perfect surface, the final part has the same visual and tactile properties as a production ABS part. It gives you a prototype that you can confidently show to anyone.

What if your part needs to be transparent? Like a light pipe, a lens, or a see-through cover.

For this, we use a completely different family of polyurethane resins. These are "water-clear" resins. They are specially formulated to cure with perfect optical clarity and to resist yellowing over time from UV exposure.

These materials can perfectly mimic the properties of Polycarbonate (PC) or Acrylic (PMMA). The key to a truly crystal-clear part is a combination of a great material and a perfect master pattern. The master pattern must be polished to a mirror-like finish. The silicone mold will copy this perfect finish, and the clear resin will then replicate it in the final part.

The versatility of polyurethane truly shines when you need soft, rubber-like parts.

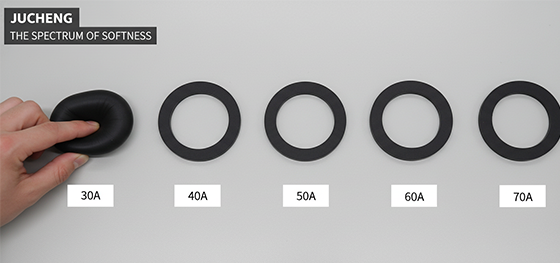

There is a huge range of "elastomeric" resins available. Their softness is measured on the Shore A hardness scale.

You can choose a resin with a hardness of Shore 30A, which feels like a very soft gel. This is great for making soft, compliant grips or pads. You can choose a Shore 70A, which feels like a tough, firm rubber, like a car tire. And you can choose anything in between.

This allows a designer to create a whole family of prototypes to test different levels of softness and find the perfect feel for their product. It is an essential tool for designing ergonomic and user-friendly products.