ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Allen Xiao Publish Time: 2025-11-26 Origin: Site

Someone in your design meeting says, "Let's use PU injection moulding for this part." This simple phrase can cause huge confusion. It sounds specific. But it is not.

This is because "pu injection moulding" can refer to two completely different manufacturing universes. Choosing the wrong one can be a disaster for your project's budget, timeline, and final quality.

One path involves a chemical reaction. The other involves brute force. One is for huge parts. The other is for small parts. This guide will clear up the confusion. It is a map to the two worlds of polyurethane.

content:

The confusion starts with the material itself: Polyurethane (PU). PU is not a single plastic. It is a family. And this family has two major branches.

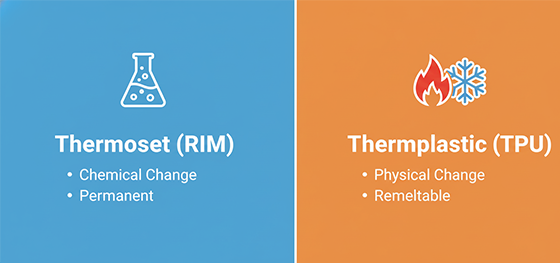

The first branch is "Thermoset" Polyurethane. This is the type used in reaction injection molding (RIM). It starts as two liquids that react and cure into a solid. Once it is solid, it is permanent. You cannot melt it down and reuse it. It is a one-way chemical change.

The second branch is "Thermoplastic" Polyurethane, or TPU. This material comes in the form of solid pellets. You melt it, inject it, and it cools back into a solid. But this is a physical change, not a chemical one. You can re-melt and re-form a TPU part.

These two branches lead to two completely different manufacturing processes, each with its own unique strengths.

This is the world of Reaction Injection Molding, or RIM. This process is the master of making large, lightweight, and complex parts.

Because it starts with low-viscosity liquids and uses a low-pressure filling process, RIM is perfect for parts that are simply too big for traditional molding. Think of a huge tractor body panel or a massive medical device enclosure.

The low pressure also means the molds can be made from aluminum, which is much cheaper and faster to produce than steel. This makes RIM an incredibly cost-effective solution for mid-volume production runs (from a few hundred to a few thousand parts).

So, if your "PU part" is a big, structural, or cosmetic component, the type of pu injection moulding you are actually looking for is RIM.

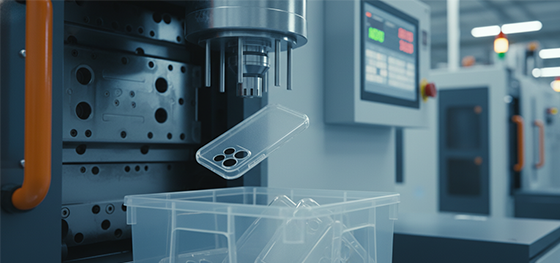

This is the world of traditional, high-pressure injection molding. It is the master of making small, tough, and highly detailed parts in very high volumes.

This process uses solid TPU pellets. The pellets are melted in the machine's barrel and then injected into a hardened steel mold at extremely high pressure.

TPU itself is an amazing material. It is known for its incredible abrasion resistance, toughness, and elasticity. It feels like a very tough rubber. This makes it perfect for parts that need to be durable and flexible. Think of caster wheels, power tool grips, and protective phone cases.

This process is extremely fast, with cycle times of just a few seconds. It is the ideal choice for making millions of small, identical parts.

So, how do you know which path is right for your project? You need to ask yourself three questions.

First, what is the size of my part? If it is larger than a shoebox, you should be thinking about RIM. If it is smaller than your hand, you should be thinking about TPU injection molding.

Second, what is my production volume? If you need 500 parts, the lower tooling cost of RIM is a huge advantage. If you need 5 million parts, the high speed of TPU injection molding is the only logical choice.

Third, what specific properties do I need? If you need a huge, lightweight structural foam part, only RIM can do that. If you need a tiny, super abrasion-resistant gear, TPU is the answer.

The world of pu injection moulding is confusing. It is easy to go down the wrong path.

This is why it is critical to work with a manufacturing partner who is an expert in both worlds. A partner who does not just try to sell you the one process they happen to have.

At JUCHENG, we have deep expertise in both low-pressure reaction injection molding and high-pressure thermoplastic injection molding.

We can look at your project and give you unbiased, expert advice. We can help you ask the right questions and guide you to the manufacturing path that is truly the best fit for your part, your budget, and your business goals. This is the value of a true, full-service partner.