ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-11-26 Origin: Site

Think of a bone. It is not a solid, heavy block. It is a brilliant structure. A hard, dense outer shell with a lightweight, web-like matrix inside. This is how nature creates incredible strength without incredible weight.

In advanced manufacturing, we have a process that mimics this exact principle. It takes the great advantages of reaction injection molding (RIM) and gives the final part an internal skeleton.

This advanced process is called reinforced reaction injection moulding, or SRIM. It is the key to creating huge, lightweight parts that are also incredibly strong and stiff.

content:

Standard reaction injection molding is fantastic for making large, lightweight parts with a beautiful surface finish. Think of a bumper or a large enclosure.

But these parts are essentially hollow shells made of unreinforced plastic. They are tough, but they are not exceptionally stiff. For a part that just needs to look good and resist impacts, this is perfect.

But what if your part needs to be a primary structural component? What if it needs to bear a heavy load without flexing? What if it needs the stiffness of a composite material? A hollow plastic shell is not enough. The part needs a backbone.

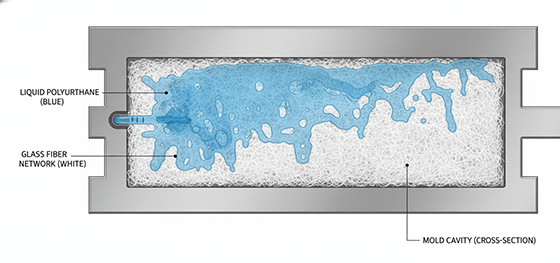

This is the core idea of reinforced reaction injection moulding. Before we inject the liquid polyurethane, we strategically place a "skeleton" inside the mold.

This skeleton is a pre-formed mat of reinforcing fibers. Most commonly, this is a mat of chopped or continuous glass fibers. For even higher performance, it can be carbon fiber.

This fiber "preform" is cut to the exact shape of the part. It is placed into the empty mold cavity. This is the step that turns a simple molding process into a composite manufacturing process.

Now, the RIM process begins. But it is a little different.

The mold is closed, gently clamping down on the fiber mat. Then, the mixed, low-viscosity liquid polyurethane is injected into the mold at a low pressure.

The liquid flows into the mold. As it spreads, it completely surrounds and saturates, or "infuses," the entire fiber skeleton. It fills every microscopic gap between the fibers.

Then, the chemical reaction happens. The liquid polyurethane cures into a solid plastic matrix all around the fibers. It permanently locks the skeleton in place. The result is no longer just a plastic part. It is a true composite. A solid, integrated structure of plastic and fiber.

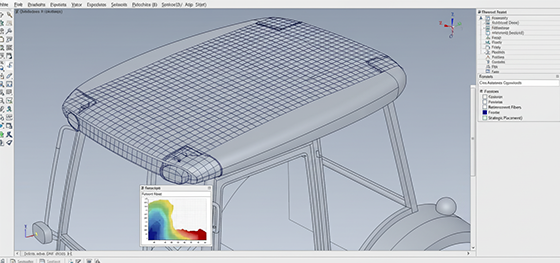

The beauty of SRIM is its intelligence. You do not have to put fibers everywhere.

Using engineering analysis tools, a designer can determine which areas of a large part will experience the most stress. You can then design a fiber preform that is only placed in those high-stress areas.

For example, on a large tractor roof, you might only put reinforcement around the mounting points and in the center, leaving the other areas as unreinforced plastic.

This is an incredibly efficient way to build. It gives you strength and stiffness exactly where you need it, without adding the weight and cost of reinforcing the entire part. It is a highly optimized structural solution.

The final SRIM part has a remarkable combination of properties.

It has the Class-A surface finish and design freedom of a standard RIM part. But it has the stiffness and strength of a composite. Its strength-to-weight ratio can be far superior to steel or aluminum.

This is why reinforced reaction injection moulding is a key technology in the automotive industry. It is used to make lightweight, strong, and complex parts like door panels, floor pans, and spare tire covers.

It is also used in many other industries, for everything from agricultural equipment to wind turbine housings. It is the perfect solution for any project that needs a large, lightweight part with serious structural integrity. It is the process that gives plastic a strong backbone.