ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 4 Author: Site Editor Publish Time: 2023-11-16 Origin: Site

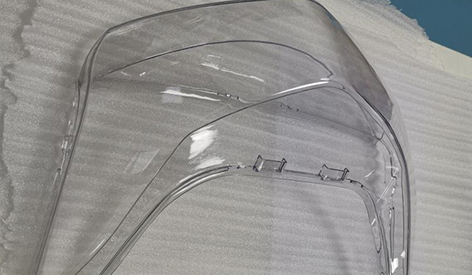

The requirements for 5-axis CNC machining of car light housings include:

Complex Geometry: aoto light housings often have intricate shapes and curves. 5-axis CNC machining allows for simultaneous movement along multiple axes, facilitating the processing of complex geometries.

High Precision: aoto light housings demand high precision due to their impact on both appearance and performance. 5-axis CNC machining must provide accurate processing to ensure the dimensions and shapes meet design specifications.

Surface Quality: Smooth surfaces are often required for car light housings. 5-axis CNC machining, with its ability to handle complex surfaces, contributes to achieving higher quality surface finishes.

Material Adaptability: aoto light housings can be made from various materials, including plastics, aluminum alloys, magnesium alloys, etc. 5-axis CNC machining should accommodate different material types, providing appropriate tooling and machining parameters.

Cooling and Cutting Parameters: Given the often complex contours and details involved in car light housing machining, effective cooling systems are required to prevent material overheating. Proper cutting parameters must be established to optimize the machining process.

Process Planning: Careful planning of the machining process is crucial for 5-axis CNC machining. Toolpaths need to be well-planned to ensure stable tool movement throughout the process, avoiding interferences and collisions.

Safety Measures: 5-axis CNC machining involves complex machine and tool movements. Adequate safety measures are essential to prevent accidents and ensure the well-being of operators.

By meeting these requirements, 5-axis CNC machining can efficiently produce high-quality, precise, and aesthetically pleasing car light housing components.