ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Site Editor Publish Time: 2023-10-25 Origin: Site

The manufacturing of automobile cylinder prototypes involves various critical factors:

Material Selection: Choosing the right material for the cylinder, typically cast iron or aluminum, considering strength, weight, and heat resistance.

Design and CAD Modeling: Creating a detailed 3D model of the cylinder design, ensuring proper dimensions, cooling passages, and mounting points.

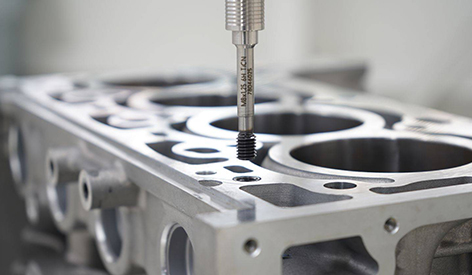

Machining Process: CNC machining or other methods for shaping the cylinder, drilling and tapping holes for bolts and sensors, and ensuring precise tolerances.

Surface Finish: Achieving a smooth surface to minimize friction, heat, and wear, which is crucial for engine performance.

Heat Treatment: If required, heat treatment processes for enhancing the material's strength and durability.

Testing and Validation: Rigorous testing for compression, leak, and thermal performance to ensure the prototype functions as intended.

Optimized Cooling: Designing efficient cooling passages to prevent overheating.

Weight and Balance: Ensuring the cylinder's weight and balance are suitable for the engine and vehicle.

Sealing and Gasket Compatibility: Designing for proper gasket sealing and compatibility with engine components.

Safety and Regulatory Compliance: Meeting safety standards and regulatory requirements for automotive components.

Cost Considerations: Balancing costs to meet budget constraints while maintaining quality.

Scalability: Considering the potential for mass production and the need for tooling and molds.

Manufacturability: Ensuring that the prototype design is manufacturable within a reasonable timeframe and cost.

Environmental Impact: Addressing sustainability and environmental concerns in materials and manufacturing processes.

Automobile cylinder prototypes are crucial for testing and validating engine designs before mass production, making these factors key to their successful manufacturing.