ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 3 Author: Site Editor Publish Time: 2023-11-20 Origin: Site

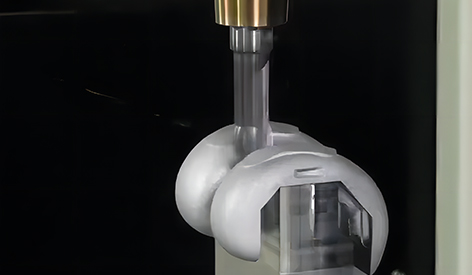

What should we pay attention to in 5-axis CNC machining of knee joint bones for precision medical device parts?

When performing 5-axis CNC machining for precision medical device parts such as knee joint bones, several critical considerations should be taken into account to ensure accuracy, quality, and compliance with medical standards. Here are some key aspects to pay attention to:

Material Selection: Choose a biocompatible material suitable for medical applications. Common materials for medical device components include titanium alloys and medical-grade stainless steel.

Tool Selection: Use appropriate cutting tools designed for precision machining of medical-grade materials. Tools should be sharp, and their selection should consider factors like material hardness and cutting forces.

Fixturing and Workholding: Securely fix the knee joint bone components during machining to prevent vibration and ensure stability. Consider custom fixtures that allow access to all machining surfaces.

CAD/CAM Software Optimization: Utilize advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to optimize toolpaths, reducing unnecessary tool changes and minimizing machining time.

Surface Finish Requirements: Medical device parts often have stringent surface finish requirements. Pay attention to toolpath strategies and machining parameters to achieve the desired surface finish without the need for additional post-processing.

Tolerance and Precision: Medical device parts, especially those for knee joints, demand tight tolerances. Ensure that the CNC machine is capable of achieving the required precision, and regularly check and calibrate the machine for accuracy.

Cooling and Lubrication: Implement effective cooling and lubrication systems to dissipate heat during machining. This is crucial for preventing thermal damage to the material and ensuring dimensional stability.

Quality Control and Inspection: Implement a robust quality control process, including in-process inspections and final inspections, to verify that the machined components meet the required specifications and tolerances.

Cleanroom Protocols: If the medical device requires assembly or packaging in a cleanroom environment, take appropriate precautions to prevent contamination during the machining process.

Documentation and Traceability: Maintain comprehensive documentation throughout the manufacturing process, including material certificates, machining parameters, and inspection records. This is essential for traceability and compliance with medical device regulations.

Operator Training: Ensure that machine operators are well-trained in both CNC machining techniques and the specific requirements of medical device manufacturing. Continuous training and skill development are crucial.

By addressing these considerations, manufacturers can enhance the precision, quality, and reliability of knee joint bone components produced through 5-axis CNC machining for medical devices. Additionally, it's important to stay informed about any relevant updates to medical device regulations and standards.