ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 6 Author: Site Editor Publish Time: 2024-04-18 Origin: Site

Introduction

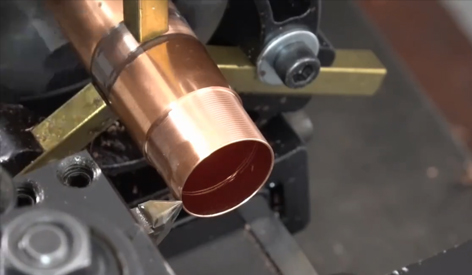

Brass CNC-turned parts play a crucial role in various industries, offering a balance of durability, corrosion resistance, and aesthetic appeal. This guide delves into the world of brass CNC turned parts, exploring their benefits, cost-effectiveness, and best practices for maximizing value.

1. Understanding Brass CNC Turned Parts

· Overview of brass as a material for CNC turning, highlighting its properties and advantages.

· Explanation of CNC turning process for brass parts, including precision machining techniques.

· Benefits of using brass CNC turned parts in engineering and manufacturing applications.

2. Cost-Efficiency in Brass CNC Turning

· Factors influencing the cost of brass CNC turned parts, such as material selection and complexity of designs.

· Strategies for achieving cost-efficiency without compromising quality, such as optimizing tool paths and reducing waste.

· Comparison of brass CNC turning costs with other manufacturing methods.

3. Best Practices for Brass CNC Turning

· Importance of design optimization for cost-effective brass CNC turning, focusing on minimizing material usage and machining time.

· Utilizing advanced CNC machining technologies for improved accuracy and efficiency.

· Quality control measures to ensure precise dimensions and surface finish in brass CNC turned parts.

4. Applications of Brass CNC Turned Parts

· Explore diverse industries benefiting from brass CNC turned parts, such as automotive, aerospace, electronics, and plumbing.

· Case studies showcasing successful applications of brass CNC turned parts in real-world projects.

· Highlighting the versatility of brass CNC turned parts for complex geometries and tight tolerances.

5. Advantages of Brass CNC Turning

· Discuss the unique advantages of brass CNC turning, including high machinability, excellent corrosion resistance, and aesthetic appeal.

· Environmental benefits of using brass, such as recyclability and sustainability.

· How brass CNC turned parts contribute to overall product performance and longevity.

6. Cost Considerations and Budget Optimization

· Tips for optimizing budgets when manufacturing brass CNC turned parts, such as batch production and supplier partnerships.

· Evaluating total cost of ownership for brass CNC turned parts, including maintenance and lifecycle considerations.

· Strategies for negotiating competitive pricing with CNC machining providers.

Conclusion

In conclusion, brass CNC turned parts offer a winning combination of functionality, cost-efficiency, and quality. By understanding the intricacies of brass CNC turning, leveraging best practices, and exploring innovative applications, businesses can harness the full potential of brass CNC turned parts while maximizing value and minimizing costs.