ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 7 Author: Site Editor Publish Time: 2024-04-18 Origin: Site

Introduction

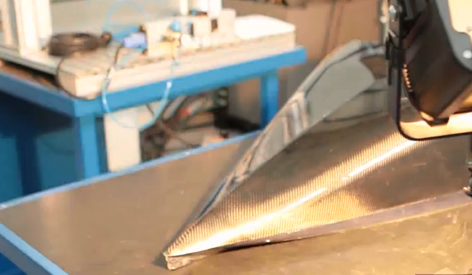

Carbon fiber prototyping stands at the forefront of advanced manufacturing, revolutionizing industries with its lightweight yet robust properties. This comprehensive guide delves into the historical journey, development milestones, and the promising future of carbon fiber prototyping.

1. Historical Roots of Carbon Fiber Prototyping

· Tracing the origins of carbon fiber and its early applications in aerospace and military sectors.

· Evolution of carbon fiber materials and manufacturing processes over the decades.

· Impact of technological advancements on the widespread adoption of carbon fiber in prototyping.

2. Development and Advancements in Carbon Fiber Prototyping

· Breakthrough innovations in carbon fiber composites, including resin systems and fiber reinforcements.

· Role of automation and digital design tools in streamlining carbon fiber prototyping workflows.

· Case studies highlighting successful applications of carbon fiber prototyping in automotive, sports equipment, and consumer goods industries.

3. Future Trends and Innovations

· Predictions for the future of carbon fiber prototyping, including advancements in material science and production techniques.

· Integration of carbon fiber with emerging technologies like 3D printing and nanotechnology.

· Environmental sustainability initiatives in carbon fiber prototyping, focusing on recyclability and eco-friendly manufacturing processes.

4. Advantages of Carbon Fiber Prototyping

· Unmatched strength-to-weight ratio of carbon fiber composites, enabling lightweight yet durable prototypes.

· High stiffness and dimensional stability, critical for precision engineering applications.

· Resistance to corrosion, fatigue, and extreme temperatures, ensuring longevity and reliability.

5. Applications Across Industries

· Automotive: Exploring how carbon fiber prototyping enhances vehicle performance, fuel efficiency, and design aesthetics.

· Aerospace: Role of carbon fiber in aircraft components, reducing weight and improving fuel economy.

· Sports and Recreation: Advantages of carbon fiber in athletic equipment such as bicycles, tennis rackets, and helmets.

· Consumer Electronics: Utilizing carbon fiber for lightweight and durable smartphone cases, laptops, and wearables.

6. Challenges and Considerations

· Cost implications of carbon fiber prototyping compared to traditional materials.

· Skills and expertise required for designing and manufacturing carbon fiber prototypes.

· Quality control measures and testing protocols to ensure compliance with industry standards.

Conclusion

As carbon fiber prototyping continues to evolve and innovate, it remains a cornerstone of modern engineering and product development. By understanding its historical trajectory, embracing technological advancements, and anticipating future trends, businesses can leverage the unparalleled benefits of carbon fiber to create cutting-edge prototypes that redefine industry standards and inspire innovation.