ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 6 Author: Site Editor Publish Time: 2024-04-11 Origin: Site

Introduction

In the realm of automotive engineering, the pursuit of excellence extends far beyond mere functionality. Every nut, bolt, and component must embody precision, resilience, and an aesthetic appeal that elevates the vehicle's allure. This article delves into the realm of CNC-machined auto parts, exploring how this advanced manufacturing process not only refines appearance but also fortifies against the relentless forces of corrosion.

Dimension 1: Material Selection

The foundation of durable auto parts begins with judicious material choices. CNC machining facilitates the use of high-grade alloys like stainless steel, aluminum, and titanium, renowned for their corrosion-resistant properties and ability to withstand harsh environmental conditions.

Dimension 2: Design Sophistication

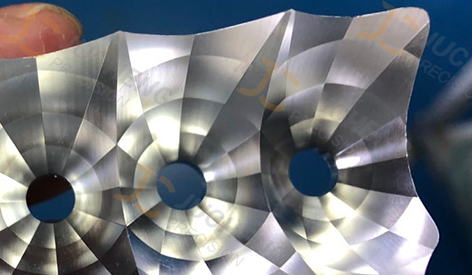

CNC machining unlocks a world of design intricacies, from sleek curves to intricate patterns. The precision offered by multi-axis CNC machines allows for flawless execution of complex geometries, enhancing the appearance and functionality of auto parts.

Dimension 3: Surface Finish

The surface finish of auto parts plays a pivotal role in aesthetics and durability. CNC machining offers a range of finishing options, including polishing, anodizing, and powder coating, each tailored to enhance appearance while providing a protective shield against corrosion.

Dimension 4: Tolerance and Fit

A hallmark of CNC-machined auto parts is their impeccable tolerance levels and perfect fitment. Every dimension is meticulously controlled, ensuring seamless integration and optimal performance within the vehicle's framework.

Dimension 5: Customization Flexibility

The versatility of CNC machining extends to customization, allowing for unique designs that reflect the brand identity and preferences of automotive manufacturers. This customization extends to surface textures, engraving, and branding, adding a personalized touch to each component.

Dimension 6: Advanced Tooling Techniques

Behind the scenes, CNC machining employs cutting-edge tooling techniques that optimize efficiency and precision. From high-speed machining to adaptive toolpath strategies, these advancements contribute to the superior quality of CNC-machined auto parts.

Dimension 7: Quality Assurance

Rigorous quality control measures are integral to CNC machining processes. Automated inspection systems, dimensional analysis, and material testing ensure that every auto part meets stringent quality standards, including resistance to corrosion.

Dimension 8: Environmental Sustainability

In an era of heightened environmental awareness, CNC machining stands out for its eco-friendly attributes. Reduced material wastage, energy-efficient processes, and recyclability of machined components contribute to a greener automotive manufacturing landscape.

Conclusion

In conclusion, the fusion of CNC machining with automotive part production heralds a new era of excellence. By prioritizing appearance refinement and corrosion resistance across these eight dimensions, CNC-machined auto parts not only enhance the visual appeal of vehicles but also endure the test of time, ensuring longevity and performance in diverse driving conditions. As automotive engineering continues to evolve, CNC machining remains a cornerstone of innovation and reliability in the quest for superior auto parts.