ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 5 Author: Site Editor Publish Time: 2024-04-15 Origin: Site

Introduction

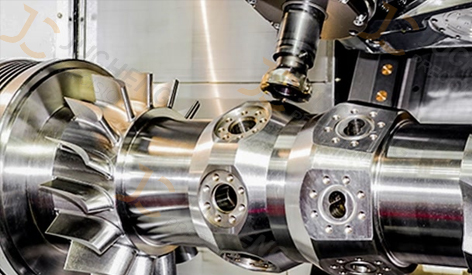

Precision metal finishing is a hallmark of excellence in modern manufacturing, weaving together stability and meticulous measurement techniques. This technical article delves into the complex world of precision metal finishing across eight dimensions and five directions, illuminating its meaning, methods, challenges, and advancements. Through the lens of innovation and quality, we explore how stability and measurement can be fused to elevate metal finishing to an unparalleled level of precision and excellence.

Dimension 1: Understanding Precision Metal Finishing

Precision metal finishing encompasses a spectrum of surface treatment processes aimed at enhancing the aesthetics, functionality, and durability of metal components. From deburring and polishing to coating and plating, each technique plays a crucial role in achieving the desired finish and performance characteristics.

Dimension 2: Stability in Process Control

Process stability is paramount in precision metal finishing to ensure consistent results and meet stringent quality standards. Employing advanced process control techniques, such as statistical process control (SPC) and Six Sigma methodologies, minimizes variability, reduces defects, and enhances overall process stability.

Dimension 3: Importance of Measurement in Metal Finishing

Accurate measurement is the cornerstone of precision metal finishing, facilitating quality assurance and conformity to specifications. Utilizing precision measurement tools, such as coordinate measuring machines (CMMs), optical profilometers, and surface roughness testers, enables precise dimensional analysis and surface characterization.

Dimension 4: Advanced Surface Treatment Techniques

Advancements in surface treatment techniques have revolutionized precision metal finishing. From electroplating and anodizing to shot peening and laser engraving, modern technologies offer diverse options to achieve desired surface properties, including corrosion resistance, wear resistance, and aesthetic appeal.

Dimension 5: Quality Assurance and Inspection

Robust quality assurance and inspection protocols are integral to precision metal finishing. Implementing rigorous inspection regimes, including visual inspections, non-destructive testing (NDT), and chemical analysis, ensures that finished components meet exacting quality standards and customer requirements.

Direction 1: Innovations in Coating Technologies

Innovative coating technologies, such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition), provide enhanced surface hardness, lubricity, and thermal resistance, expanding the capabilities of precision metal finishing in demanding applications.

Direction 2: Environmental Sustainability

Embracing environmentally sustainable practices is a growing trend in precision metal finishing. Adopting eco-friendly coatings, recycling wastewater, and minimizing chemical usage contribute to reducing environmental impact and aligning with sustainability goals.

Direction 3: Digital Integration and Automation

Digital integration and automation are reshaping precision metal finishing processes. IoT-enabled sensors, data analytics, and robotic automation optimize process control, improve efficiency, and enable predictive maintenance, enhancing overall productivity and quality.

Direction 4: Customization and Tailored Solutions

The demand for customized finishes and tailored solutions is driving innovation in precision metal finishing. Customized coatings, color matching, and surface texturing cater to diverse industry needs, fostering product differentiation and customer satisfaction.

Direction 5: Training and Skills Development

Investing in training and skills development is critical for achieving excellence in precision metal finishing. Continuous education on new technologies, safety protocols, and quality standards empowers workforce proficiency and ensures adherence to best practices.

Conclusion

Precision metal finishing embodies a fusion of artistry, technology, and precision, creating surfaces of unparalleled quality and functionality. By embracing stability, meticulous measurement, and advancing surface treatment techniques across the eight dimensions and five directions outlined in this article, manufacturers can unlock new levels of excellence, meet evolving customer expectations, and drive innovation in the metal finishing industry. As the industry continues to evolve, prioritizing stability and measurement will remain fundamental to achieving enduring success and delivering exceptional metal finishing solutions.