2025-12-02 What is a prototype? Is it just a shape? A rough approximation of your idea? Or is it a convincing replica, a stand-in that can fool the senses and tell a powerful story?For designers and engineers preparing for a critical trade show, a high-stakes investor pitch, or a final round of user testing, a

Read More

2025-11-28 You have a project. You need 50 high-quality prototypes. You get a quote. But what does that number on the quote actually mean? Is it a good value? Where is your money really going?Understanding the vacuum casting cost is not just about budgeting. It is about making smart investment decisions. It is

Read More

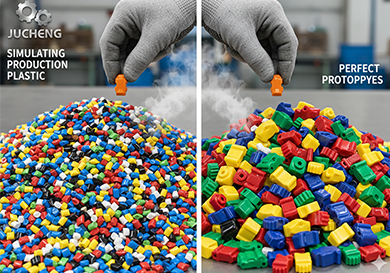

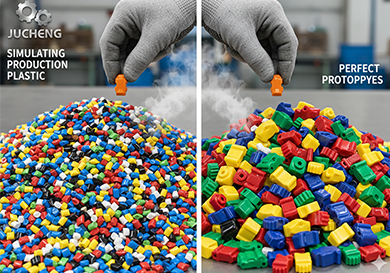

2025-11-28 Your prototype needs to do more than just look right. It needs to feel right. When an investor or a potential customer holds it in their hands, it must feel like the real, final product.But the Vacuum Casting process does not use the same plastics as mass production. It uses a family of materials ca

Read More

2025-11-28 As a designer, it feels like magic. You spend weeks perfecting a 3D model on your computer. You send the file to a manufacturing partner. A short time later, a box arrives with 20 perfect, physical copies of your design.The surface finish is flawless. The details are crisp. They feel like final prod

Read More

2025-11-28 Your startup has a brilliant new product. You need 50 perfect units for a critical investor demo next month. You search online for a vacuum casting service and get a dozen quotes. One is significantly cheaper than the others. Should you take it?This is a dangerous moment. Choosing the wrong partner

Read More

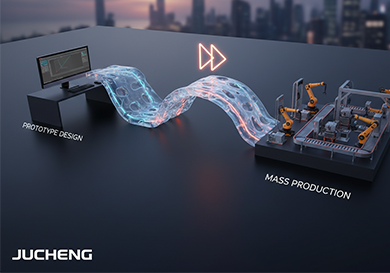

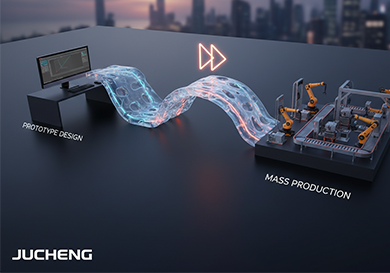

2025-11-28 Your design is finalized. Your engineering tests are complete. You are ready for the market. There is just one problem. The steel injection mold for mass production will take 12 weeks to build.Twelve weeks. In today's market, that is an eternity. It is a huge, risky gap in your project timeline. You

Read More

2025-11-26 Think of a bone. It is not a solid, heavy block. It is a brilliant structure. A hard, dense outer shell with a lightweight, web-like matrix inside. This is how nature creates incredible strength without incredible weight.In advanced manufacturing, we have a process that mimics this exact principle.

Read More

2025-11-26 Your new protective case has a beautiful foam insert. It holds the product perfectly. But after a few uses, a disaster. The foam starts to tear. It feels lifeless. It loses its bounce. It no longer holds the product securely.What went wrong? You specified a foam material. But not all foams are creat

Read More

2025-11-26 Your part needs to be flexible and soft, like rubber. But it also needs to be tough enough to survive constant scraping and impact, like a hard plastic. What do you choose?This is a classic engineering trade-off. Rubber is soft, but it wears out quickly. Hard plastic is durable, but it can be brittl

Read More

2025-11-26 Someone in your design meeting says, "Let's use PU injection moulding for this part." This simple phrase can cause huge confusion. It sounds specific. But it is not.This is because "pu injection moulding" can refer to two completely different manufacturing universes. Choosing the wrong one can be a

Read More