2025-11-26 Imagine designing a product not as an assembly of small pieces, but as a single, seamless, monolithic form. A car door with no separate trim pieces. A chair that flows from leg to backrest in one unbroken curve.For decades, this vision was mostly a dream for designers. The immense cost and limitatio

Read More

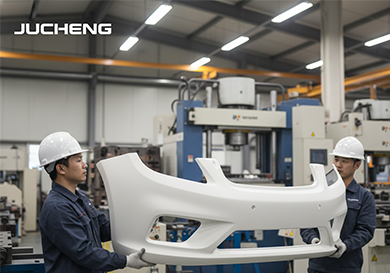

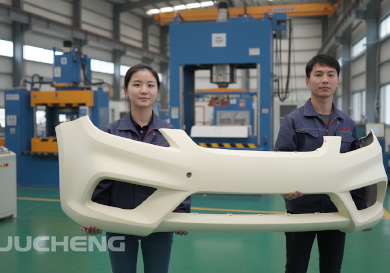

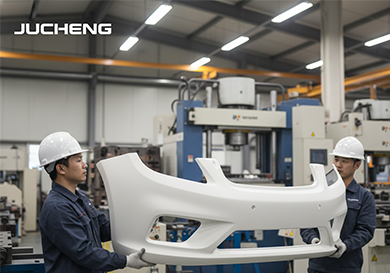

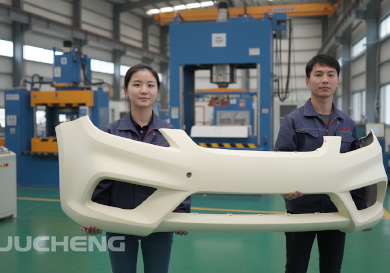

2025-11-26 Your new product is big. A full-size automotive bumper. A large medical device enclosure. An equipment panel that is a meter wide.You face a difficult choice. Traditional injection molding for a part this size requires a steel tool that costs a fortune and takes months to build. 3D printing is too s

Read More

2025-11-22 What if a single material could be a rock-hard structural component, a tough and flexible bumper, and a soft, cushiony foam? It sounds like science fiction. But it is not.This is the incredible versatility of polyurethane. It is the undisputed star of the reaction injection molding (RIM) world. It i

Read More

2025-11-22 Is your manufacturing process limiting your design? Or is it liberating it? This is one of the most important questions a product designer can ask.For too long, great ideas have been constrained by the harsh realities of traditional manufacturing. A beautiful, flowing curve is straightened because i

Read More

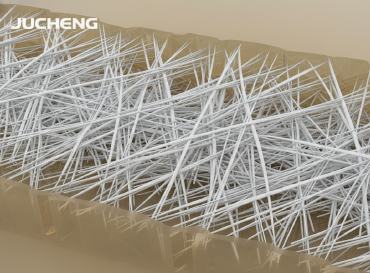

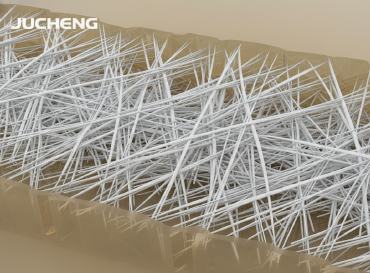

2025-11-22 Think of a bone. It is not a solid, heavy block. It is a brilliant structure. A hard, dense outer shell with a lightweight, web-like matrix inside. This is how nature creates incredible strength without incredible weight.In advanced manufacturing, we have a process that mimics this exact principle.

Read More

2025-11-22 Watching a traditional injection molding machine is watching an act of brute force. Molds slam shut. Hot plastic is forced in under incredible pressure. It is loud. It is powerful.Then you watch a reaction injection molding (RIM) machine. It is quiet. The material flows in gently. A few minutes late

Read More

2025-11-22 Your new product is big. A full-size automotive bumper. A large medical device enclosure. An equipment panel that is a meter wide.You face a difficult choice. Traditional injection molding for a part this size requires a steel tool that costs a fortune and takes months to build. 3D printing is too s

Read More

2025-11-21 Your 3D printer has just finished a 12-hour print. The part looks perfect. You take it off the build plate. You apply a small amount of force to test it. And snap. It breaks cleanly in two, right along the layer lines.This is the nightmare of every engineer who uses 3D printing for functional parts.

Read More

2025-11-21 When a product reaches the end of its life, where does it go? For decades, the answer for most plastic products was a landfill. A dead end.But a new generation of designers, engineers, and consumers is asking a better question. Can the end be a new beginning?This question is at the heart of a design

Read More

2025-11-21 What is the integrity of a product? It is a form of honesty. It is the promise that a product is what it appears to be. A flat surface should be truly flat. A straight edge should be truly straight.This is not just about aesthetics. It is about function. A baseplate that is not flat will cause the e

Read More