Sheet metal screws are indispensable fasteners in manufacturing, offering reliable joining solutions for thin metal sheets and other materials. These specialized screws are designed with sharp threads and unique head styles to ensure secure fastening, vibration resistance, and durability. Their applications span across industries, including automotive, aerospace, electronics, and construction. This article explores the design, types, and applications of sheet metal screws in manufacturing, with a particular focus on their role in sheet metal manufacturing.

Understanding Sheet Metal Screws

Sheet metal screws differ from standard screws due to their threading and tip design. They feature a fully threaded shank with sharp, aggressive threads that cut into metal, plastic, or composite materials without requiring a pre-tapped hole. The most common materials used for these screws include stainless steel, carbon steel, and aluminum, often coated with zinc or other finishes to enhance corrosion resistance.

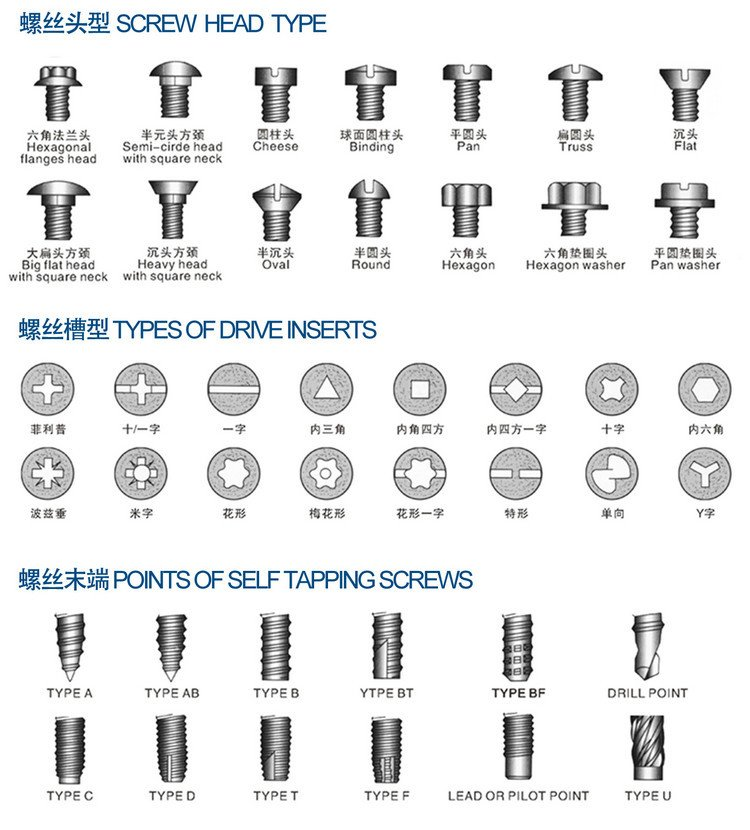

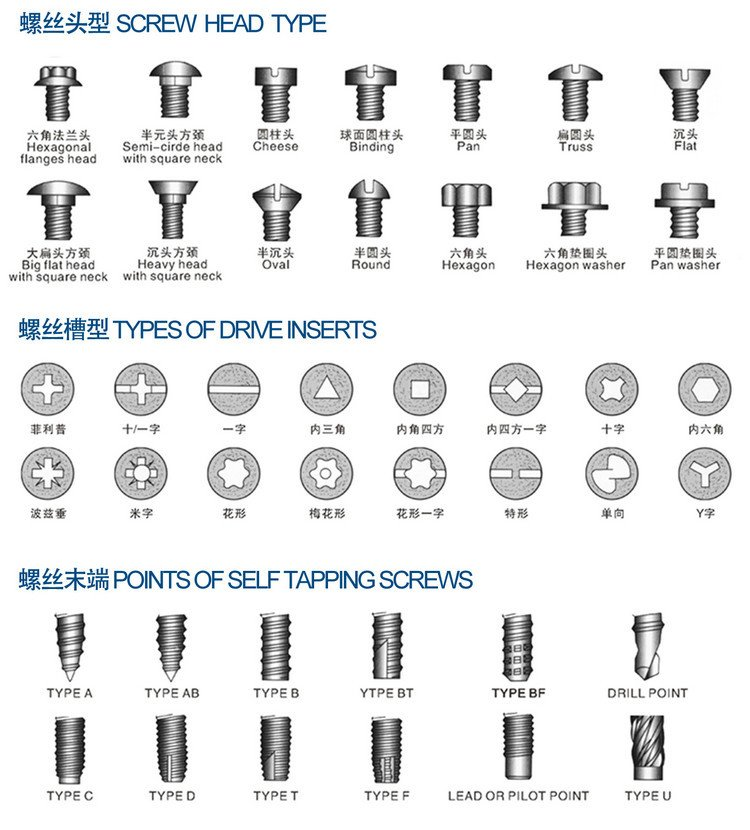

Key Features:

- Sharp Threads: Designed to penetrate and grip sheet metal effectively.

- Variety of Head Styles: Pan head, flat head, hex head, and truss head options for different applications.

- Self-Tapping or Self-Drilling: Some variants can drill their own holes, reducing the need for pre-drilling.

- Corrosion Resistance: Coatings such as zinc plating or galvanization improve longevity in harsh environments.

Types of Sheet Metal Screws

Manufacturers use different types of sheet metal screws depending on material thickness, assembly requirements, and environmental conditions.

1. Self-Tapping Sheet Metal Screws

These screws create their own threads as they are driven into the material, eliminating the need for a pre-threaded hole. They are ideal for thin metal sheets and plastics.

2. Self-Drilling Sheet Metal Screws

Equipped with a drill-like tip, these screws can pierce through metal without requiring a pilot hole, significantly speeding up assembly processes.

3. Hex Head Sheet Metal Screws

Featuring a hexagonal head, these screws allow for high torque application using a wrench or socket, making them suitable for heavy-duty fastening.

4. Pan Head and Flat Head Sheet Metal Screws

Pan head screws provide a slightly rounded top, while flat head screws sit flush with the material surface, offering a smooth finish for aesthetic or safety reasons.

Applications in Manufacturing

Applications in Manufacturing

Sheet metal screws are widely used across multiple industries due to their versatility and strength.

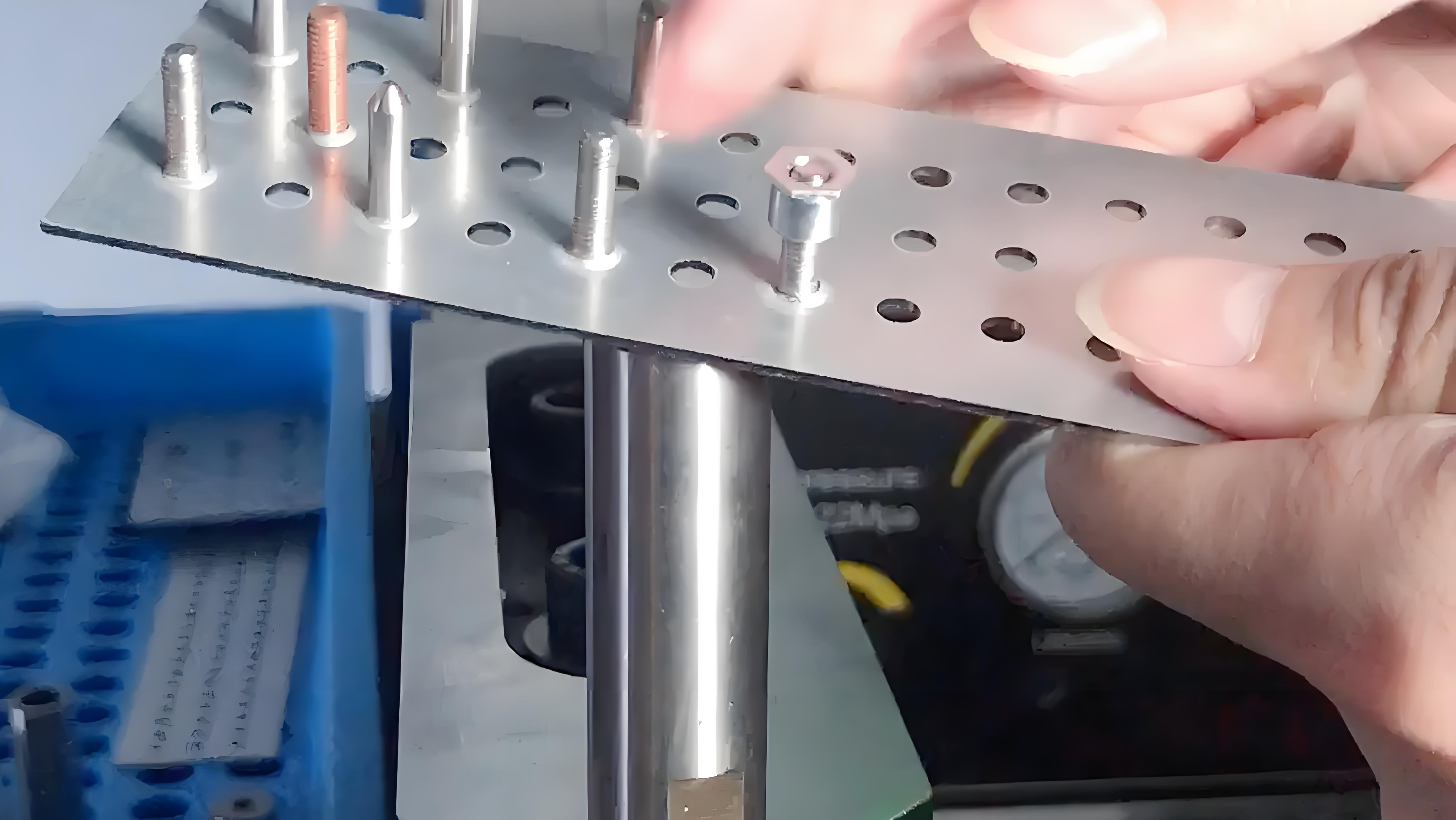

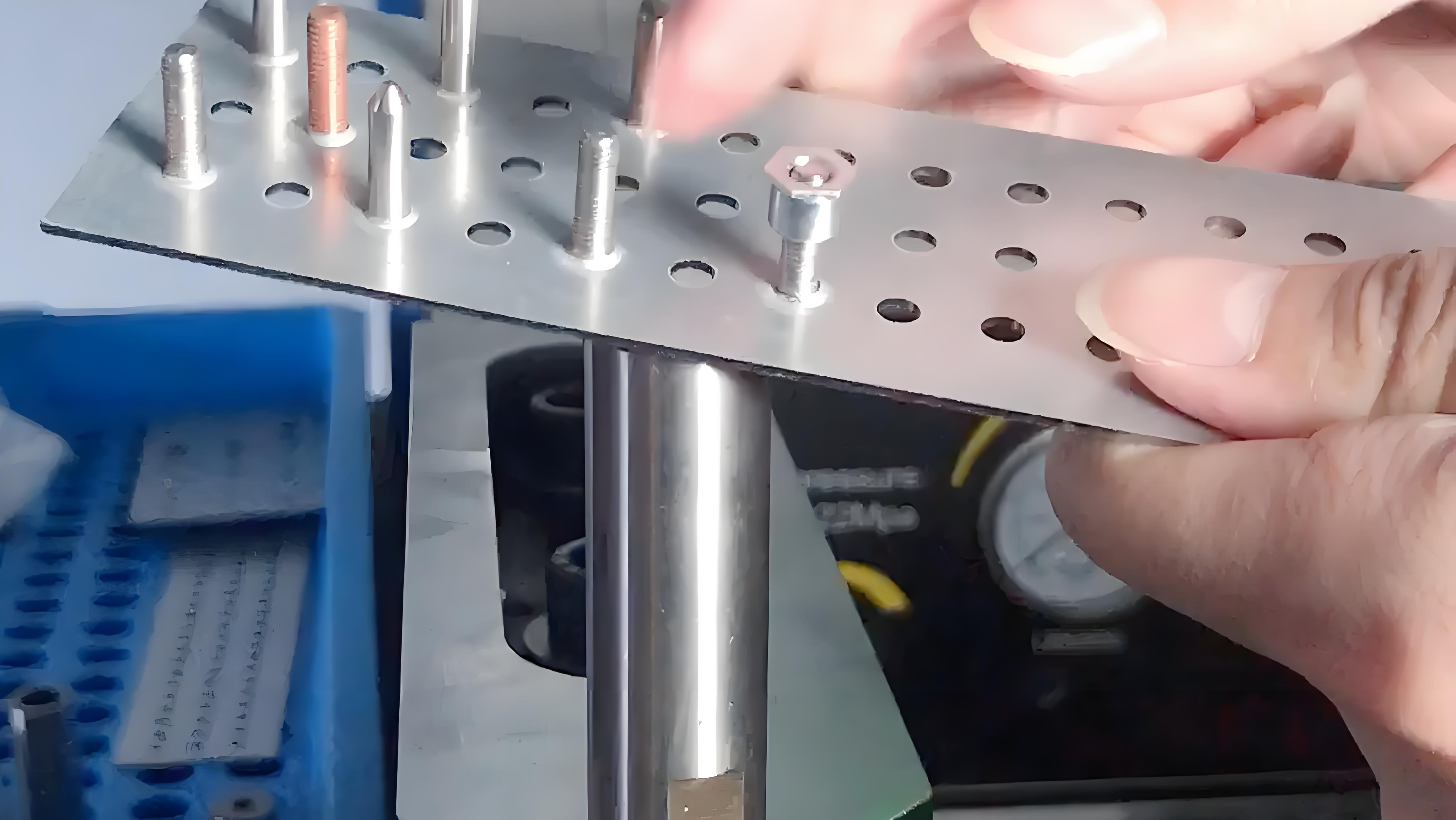

1. Sheet Metal Manufacturing

In sheet metal manufacturing, screws are essential for assembling HVAC ducts, electrical enclosures, and metal cabinets. Their ability to securely fasten thin metal sheets without welding makes them a preferred choice for lightweight yet durable constructions. Self-drilling screws, in particular, enhance efficiency in high-volume production lines by reducing preparation time.

2. Automotive Industry

Automakers rely on sheet metal screws for assembling body panels, interior trim, and undercarriage components. Their vibration-resistant properties ensure long-term stability in high-stress environments.

3. Aerospace and Aviation

Aircraft manufacturers use corrosion-resistant sheet metal screws to assemble lightweight aluminum and composite structures, where reliability and weight savings are critical.

4. Electronics and Appliances

These screws secure casings, brackets, and internal components in devices such as computers, refrigerators, and industrial machinery.

5. Construction and Roofing

In construction, sheet metal screws fasten metal roofing, siding, and structural frameworks, providing weatherproof and durable joints.

Best Practices for Using Sheet Metal Screws

To ensure optimal performance, manufacturers must follow best practices when selecting and installing sheet metal screws.

1. Material Compatibility

Choosing the right screw material (e.g., stainless steel for corrosive environments) prevents premature failure.

2. Proper Sizing

Using screws with the correct length and diameter ensures sufficient thread engagement without damaging the material.

3. Pilot Holes (When Necessary)

While self-tapping screws eliminate the need for pre-threading, thicker materials may still require pilot holes to prevent deformation.

4. Torque Control

Over-tightening can strip threads, while under-tightening may lead to loose joints. Using torque-controlled tools ensures consistent fastening.

5. Corrosion Protection

In outdoor or high-moisture applications, screws with protective coatings (e.g., zinc, ceramic, or PTFE) should be used.

Innovations in Sheet Metal Screw Technology Advancements in fastener technology continue to improve the performance and efficiency of sheet metal screws. 1. High-Strength Alloys New alloy compositions enhance tensile strength and fatigue resistance, allowing screws to withstand extreme conditions. 2. Anti-Vibration Designs Thread-locking features and nylon patches reduce loosening caused by vibrations, extending the lifespan of assemblies. 3. Automated Installation Systems Robotic screwdriving systems in manufacturing plants ensure precision and consistency in high-volume production. 4. Environmentally Friendly Coatings Non-toxic, RoHS-compliant coatings are becoming standard in electronics and consumer goods manufacturing. Sheet metal screws play a crucial role in modern manufacturing, offering a reliable and efficient fastening solution for a wide range of applications. From sheet metal manufacturing to aerospace and construction, these screws ensure durable and secure assemblies. By understanding their types, applications, and best practices, manufacturers can optimize their production processes and improve product longevity. As technology advances, sheet metal screws will continue to evolve, meeting the demands of increasingly complex and high-performance industrial applications.

Innovations in Sheet Metal Screw Technology Advancements in fastener technology continue to improve the performance and efficiency of sheet metal screws. 1. High-Strength Alloys New alloy compositions enhance tensile strength and fatigue resistance, allowing screws to withstand extreme conditions. 2. Anti-Vibration Designs Thread-locking features and nylon patches reduce loosening caused by vibrations, extending the lifespan of assemblies. 3. Automated Installation Systems Robotic screwdriving systems in manufacturing plants ensure precision and consistency in high-volume production. 4. Environmentally Friendly Coatings Non-toxic, RoHS-compliant coatings are becoming standard in electronics and consumer goods manufacturing. Sheet metal screws play a crucial role in modern manufacturing, offering a reliable and efficient fastening solution for a wide range of applications. From sheet metal manufacturing to aerospace and construction, these screws ensure durable and secure assemblies. By understanding their types, applications, and best practices, manufacturers can optimize their production processes and improve product longevity. As technology advances, sheet metal screws will continue to evolve, meeting the demands of increasingly complex and high-performance industrial applications.