ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 9 Author: Site Editor Publish Time: 2024-01-22 Origin: Site

In the ever-evolving landscape of product development, the journey from rapid prototyping to Low Volume manufacturing is a critical phase. This guide provides insights into the development history, process iterations, and precautions associated with transitioning from prototyping to production.

1. Development History: Evolving Prototyping Landscape

Traditional Prototyping: Historically, product development relied on time-consuming methods such as handcrafting and model making.

Introduction of CAD: Computer-Aided Design (CAD) revolutionized prototyping by enabling digital models and simulations.

Rapid Prototyping Technologies: Advent of technologies like 3D printing accelerated prototyping, allowing quick and cost-effective model production.

2. Process Iterations: Refining Designs for Production

Conceptual Prototyping: Initial phase involves creating basic prototypes to visualize and refine the design concept.

Functional Prototypes: Iterative prototyping focuses on functionality, testing components for real-world performance.

Design Validation: Prototypes undergo rigorous testing to validate design integrity and identify potential improvements.

3. Transition to Low Volume Manufacturing: Key Steps

Material Selection: Transition requires evaluating materials for production suitability, considering factors like strength, durability, and cost.

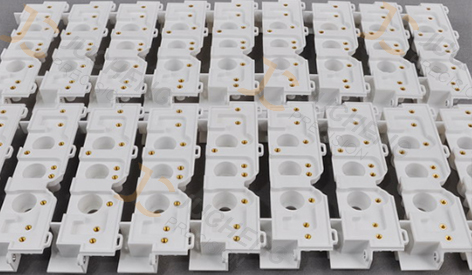

Tooling Design: Develop molds or tools needed for Low Volume manufacturing processes such as injection molding or CNC machining.

Quality Assurance: Implement quality control measures to ensure consistency across Low Volume production.

Cost Optimization: Streamline processes to minimize costs while maintaining product quality.

4. Process Considerations: Navigating Challenges

Tooling Costs: Initial investment in molds or tooling can be substantial, impacting overall production costs.

Production Scaling: Adjust production processes to accommodate Low Volumees, ensuring efficiency and cost-effectiveness.

Supply Chain Management: Low Volume manufacturing requires a responsive and flexible supply chain to meet varying demands.

Regulatory Compliance: Ensure compliance with industry regulations and standards applicable to the final product.

5. Precautions and Best Practices: Ensuring Success

Prototyping Precision: High-quality prototyping ensures accurate representation of the final product.

Collaborative Design: Foster collaboration between designers, engineers, and manufacturers for seamless transitions.

Documentation: Maintain comprehensive documentation of design iterations, material choices, and manufacturing processes.

Iterative Testing: Conduct iterative testing throughout the transition to identify and address any issues promptly.

Conclusion: Navigating the Prototyping to Production Journey

Successfully navigating the journey from rapid prototyping to Low Volume manufacturing requires a strategic approach, meticulous planning, and continuous collaboration. This guide aims to provide a roadmap for product developers, designers, and manufacturers to transition smoothly from prototyping to production, ensuring the delivery of high-quality products to the market.

content is empty!