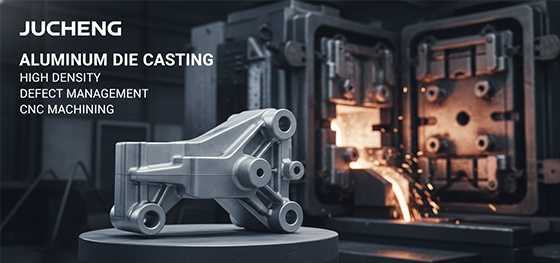

When a component requires the high strength, density, and dimensional accuracy of metal at mass-production volumes, Aluminum Die Casting is the definitive process. This highly efficient method forces molten aluminum alloy into a reusable steel mold (Die Casting Dies) under high pressure. Its success is critical for structurally important parts in automotive, electronic, and industrial applications.

The key challenge in die casting is managing internal defects, such as porosity and shrinkage, which compromise structural integrity. This guide explores the core technical processes and quality control measures necessary to guarantee the high density and flawless finish of a mass-produced aluminum component.

content:

Process Types: Cold Chamber vs. Hot Chamber Die Casting

Porosity Control: Eliminating Internal Air with Vacuum-Assisted Casting

Shrinkage Management: Designing the Tooling for Uniform Solidification

Post-Process Finishing: CNC Machining and Surface Coatings

Tooling Integrity: Managing the Thermal Fatigue of Die Casting Dies

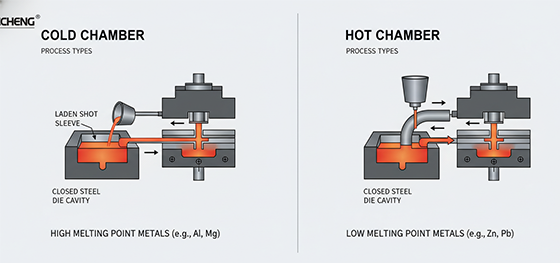

Process Types: Cold Chamber vs. Hot Chamber Die Casting

Aluminum is cast using the Cold Chamber method due to its high melting point and reactivity with the iron in the machine's "gooseneck" (the injection mechanism):

Cold Chamber Die Casting: Molten aluminum is ladled from a separate furnace into the shot chamber before each cycle. This minimizes contact time between the molten aluminum and the machine parts, making it mandatory for high-temperature alloys like aluminum and brass.

Hot Chamber Comparison: The Hot Chamber method is faster and more repeatable but is reserved for lower-melting-point, less reactive metals like zinc and magnesium, where the injection mechanism is submerged in the molten metal bath.

High Pressure Advantage: Both methods share the core principle of high injection pressure (up to 15,000 psi), which ensures the metal fills the mold quickly and densely, allowing for thin walls and fine detail.

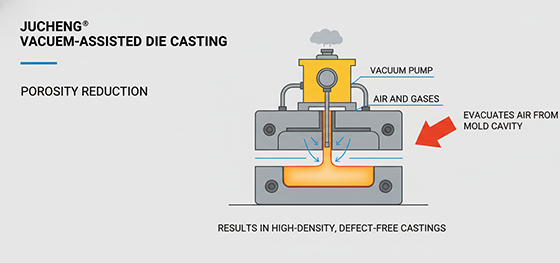

Porosity Control: Eliminating Internal Air with Vacuum-Assisted Casting

Air trapped within the mold cavity during injection is the primary cause of internal gas porosity (air bubbles), which severely compromises a part's structural strength and finish quality:

The Risk: Porosity reduces the part's cross-sectional load-bearing area, leading to premature fatigue failure. It also expands if the part is later heat-treated, causing surface blisters.

Vacuum-Assisted Die Casting: This advanced method uses a vacuum pump to remove air from the mold cavity and the molten metal before the injection. This drastically reduces porosity, resulting in denser, stronger parts that are suitable for welding and heat treatment.

Internal Channels: Aluminum Die Casting is excellent for internal features like oil galleries and cooling channels. Vacuum assistance is mandatory for these complex internal shapes to ensure complete fill and eliminate trapped air.

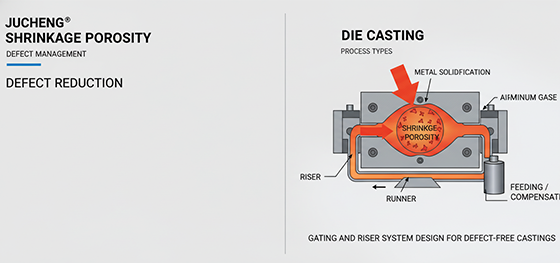

Shrinkage Management: Designing the Tooling for Uniform Solidification

Dimensional stability is threatened by shrinkage porosity—voids created when solidifying metal pulls liquid metal away from the center of the part:

Compensated Dies: The Die Casting Dies must be manufactured with a shrinkage allowance (typically 0.4% to 0.7%) to ensure the final part, after cooling, meets the required dimensions.

Gating and Feeding: The runner and gating systems are designed to ensure that the thickest sections of the component (which cool last) have a continuous supply of molten metal to "feed" the shrinkage as the material solidifies.

Die Temperature Control: Uniform cooling is maintained by circulating oil or water through the mold. Consistent mold temperature is essential to control the rate of solidification and ensure uniform shrinkage, preventing warpage.

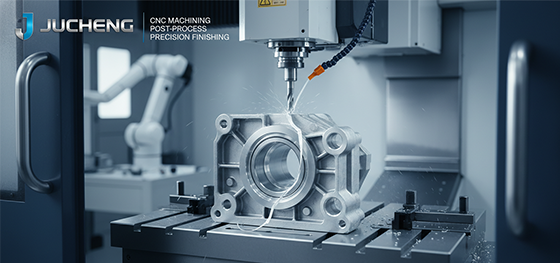

Post-Process Finishing: CNC Machining and Surface Coatings

While Die Casting achieves excellent near-net shape results, secondary processes are mandatory for features requiring tight tolerance and for final protection:

CNC Machining: Features requiring the highest precision (e.g., threaded holes, bearing seats, sealing surfaces) are finished using high-precision CNC Machining to meet tolerances tighter than the casting process alone can achieve.

Surface Coating: Aluminum die castings are often porous. Coatings like Powder Coating or Painting seal the surface and provide the required final aesthetic and environmental protection. Anodizing is sometimes used, but requires special alloys and process control.

Tooling Removal: Excess material (flash) at the mold parting line and the runner/gate system must be removed through trimming or high-speed CNC Machining, followed by aesthetic finishing.

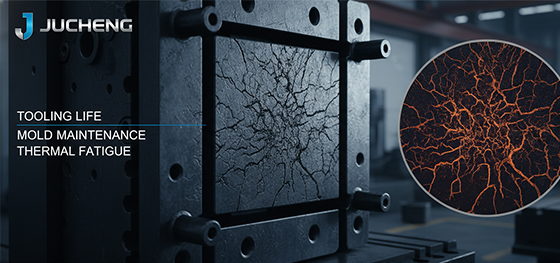

Tooling Integrity: Managing the Thermal Fatigue of Die Casting Dies

The long-term success of Aluminum Die Casting is dependent on the longevity of the steel mold, which is subjected to extreme thermal cycling:

Thermal Fatigue: The steel mold is rapidly heated by molten aluminum and then cooled by internal channels in each cycle. This massive thermal shock causes "heat checking"—fine cracks on the mold surface that transfer directly to the cast part.

Mold Maintenance: Professional manufacturers rigorously maintain and polish the molds to prevent thermal cracking from progressing and ensure the final part's surface finish remains high quality over tens of thousands of cycles.

Integrated Service: Offering in-house CNC Machining allows the manufacturer to rapidly repair or modify the Die Casting Dies, minimizing downtime and maintaining part quality.

Aluminum Die Casting is a complex, high-volume process where structural integrity relies on the mastery of thermal and pressure control. Jucheng Precision Technology integrates Vacuum-Assisted Casting, high-precision CNC Machining, and expert tooling maintenance to guarantee the densest, most dimensionally stable aluminum components.

Secure high-density, low-porosity aluminum components. Contact us today to discuss the optimal casting and finishing strategy for your mass-produced metal parts.