ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 2 Author: Site Editor Publish Time: 2025-10-08 Origin: Site

Metal etching is a vital process in modern manufacturing, enabling precise modification of metal surfaces for various industrial applications. This technique involves using chemical or physical methods to remove material selectively, creating intricate patterns, improving adhesion, or enhancing aesthetic appeal. As industries like aerospace, automotive, and electronics demand higher precision and durability, understanding different etching methods becomes crucial. This article explores key aspects of metal etching, including acid-based and chemical approaches, specific solutions, and related processes like blackening. We'll delve into how these methods integrate into broader surface treatment strategies, ensuring optimal performance and longevity for metal components. By examining real-world applications and industry standards, we aim to provide a comprehensive guide that highlights the importance of these techniques in achieving superior metal finishes.

content:

What is Metal Etching, Anyway?

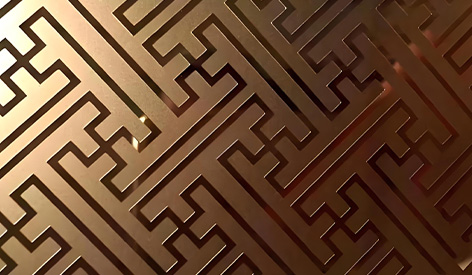

In simple terms, metal etching is like giving a piece of metal a controlled bath in a powerful liquid. The liquid slowly dissolves the parts of the metal that are not protected. So, if you want to create a design, you first cover the metal with a special protective layer. Then, you scratch your design through that layer, revealing the metal underneath. When you dip the metal in the liquid, only the scratched-away parts get "eaten," leaving your design permanently etched onto the surface.

This is great because it lets people make super detailed designs that would be very hard to carve by hand. It's used to make everything from the tiny pathways inside your video game console to the nameplate on a new bicycle.

One popular way to do this is called acid etching metal. An acid is a strong, reactive chemical (like the vinegar in your kitchen, but much stronger!). When you use acid on metal, it causes a chemical reaction that slowly "corrodes" or eats away at it.

For example, let's talk about acid etching stainless steel. Stainless steel is that shiny, hard metal used in refrigerators and sinks. It's tough to scratch, but with the right acid, artists and factories can etch beautiful designs onto it. They have to be very careful and wear safety gear because the acid can be dangerous. After the acid does its job, the metal is washed clean, and the design is left behind, looking really cool and professional.

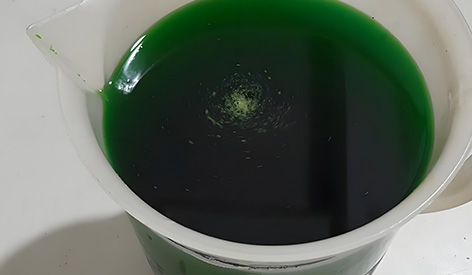

The special liquid that does the etching is often called a metal etching solution. This metal etching liquid is the secret sauce! It's carefully made so that it eats the metal at just the right speed. If it works too fast, it might ruin the design. If it's too slow, it would take forever.

Another term you might hear is chemical etching metal. This is just another way of saying that a chemical reaction is doing the work. The chemical in the liquid reacts with the metal to dissolve it. This is a very precise way to etch, perfect for creating the tiny parts inside a watch or a medical device.

Etching steel is another common job. Steel is a very strong metal used in tools, knives, and car parts. By etching steel, factories can put brand names, instructions, or measurement marks on their products. This makes the information last a long time and won't rub off like paint might.

Have you ever seen a black metal flashlight or a fancy black gun? That finish was probably created by a process called metal blackening. This is a different kind of surface treatment that often works with etching.

Metal blackening uses different chemicals to coat the metal, turning its surface a dark black color. This isn't just for looks; it also helps protect the metal from rust. Sometimes, the metal is etched first to create a rough surface that helps the black coating stick on better. It's like roughing up a smooth surface before you glue something to it!

Surface treatment is the big category that includes all of these processes. The goal is to make the metal better in some way. Maybe we want to:

Make it look more beautiful (like a piece of jewelry).

Make it easier to grip (like the handle of a tool).

Protect it from rust and wear (like the body of a car).

Help paint stick to it better.

Etching and blackening are just two of the many ways to treat a metal's surface. They are important steps in creating the strong, useful, and good-looking metal things we use every day.

In summary, metal etching and related processes like acid etching, chemical solutions, and blackening play a pivotal role in modern surface treatment. These techniques enable precise control over metal properties, supporting innovation across various sectors. As industries prioritize efficiency and sustainability, ongoing research into safer etchants and automated systems will likely enhance these methods further.

content is empty!