ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 5 Author: Allen Xiao Publish Time: 2025-09-04 Origin: Site

Selecting the correct sheet metal screw is a fundamental yet critical decision in countless manufacturing, construction, and repair applications. Using an improperly sized screw can lead to a host of issues, from stripped threads and loose fasteners to material cracking and complete joint failure. This guide provides a detailed technical overview of the various sizing systems and considerations for different types of sheet metal screws, ensuring your projects are built on a foundation of security and reliability.

content:

Sheet metal screw sizes are primarily defined by two American numbering systems: the American Standard (AS) and the American Numbering System (ANS), often referred to as "gauge" sizes. These screws are designated by a number (e.g., #6, #8, #10) which indicates the major diameter of the screw thread, followed by the length in inches or fractions of an inch. The gauge number increases with the diameter; a #6 screw has a smaller diameter than a #10. Length is measured from under the head to the tip for flat and oval heads, and from the top of the head to the tip for pan and round heads. Common diameters range from #4 (approximately 0.112 inches) to #14 (approximately 0.242 inches), with lengths varying widely to accommodate material thickness.

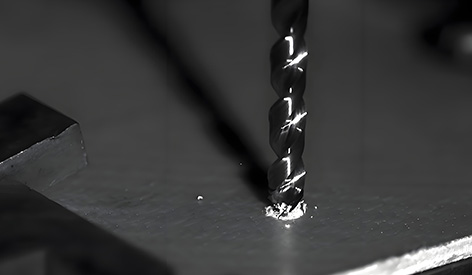

When it comes to efficiency, self drilling sheet metal screw sizes follow the same gauge numbering convention but include a critical additional feature: a drill bit-like tip. Their sizing notation often incorporates a number that indicates the thickness of metal they can drill through. For instance, a #10 screw with a "5" point is designed to drill through and form threads in 0.050 inches of steel. The most common point styles are #2 (for thinner metals), #3, #4, and #5 (for heavier gauges). Selecting the correct point length relative to the metal thickness is paramount for creating a strong, secure connection without damaging the material or the screw itself.

For standard (non-self-drilling) sheet metal screws, a pilot hole is essential to prevent material deformation and ensure clean thread engagement. A sheet metal screw pilot hole size chart is an indispensable tool for this purpose. The recommended drill bit size is slightly smaller than the screw's root diameter (the solid core of the screw between the threads). As a general rule of thumb, for a #10 screw in mild steel, a #19 or 5/32" drill bit is typically recommended. These charts vary based on the material's hardness and thickness, with harder materials often requiring a slightly larger pilot hole to avoid excessive driving torque and potential screw breakage.

Button head sheet metal screws sizes are specified using the same gauge and length system but are characterized by their low-profile, rounded dome head that provides a finished appearance. This head style is popular in applications where a sleek look is desired or where clearance is an issue, as the head is not as tall as a hex head. They are typically driven with an internal hex (Allen) key. Their sizes, such as #6-32 x 1/2" or M5 x 0.8 x 12mm, indicate the diameter and thread pitch, followed by the length, making selection straightforward for both aesthetic and functional purposes.

In global projects and machinery, metric fasteners are standard. A metric sheet metal screw size chart uses millimeters for all measurements. A typical size designation is "M5 x 0.8 x 20mm." Here, "M5" specifies a 5mm major diameter, "0.8" indicates the pitch (distance between threads) is 0.8mm, and "20mm" is the length. Metric screws offer a high degree of precision, and their charts provide similar guidance on pilot hole sizes based on the diameter and material, ensuring a perfect fit for international specifications.

Hex head sheet metal screw sizes are favored for high-torque applications. Their external hex head allows for wrench or socket driving, providing superior clamping force and making them less likely to cam out (strip) during installation compared to Phillips or slotted drives. They are available in the full range of standard gauge sizes (#6, #8, #10, etc.) and lengths, as well as in metric dimensions. The head size, which is larger than the threaded diameter, is also standardized; for example, a #10 hex head screw typically requires a 5/16" wrench.

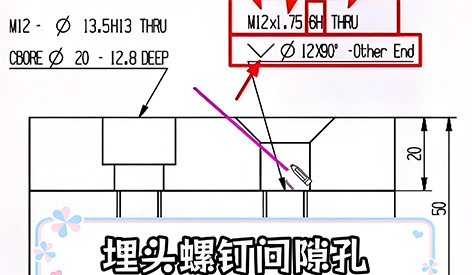

When a screw must pass freely through a top layer of material before engaging threads in a lower layer, a clearance hole is necessary. The sheet metal screw clearance hole size is deliberately larger than the screw's major diameter. For a #10 screw (major diameter ~0.190 inches), a standard clearance hole drill bit would be 13/64" (0.203 inches) or 3/16" (0.1875 inches), depending on the desired fit—close, normal, or loose. This prevents binding on the shank and ensures all clamping force is applied by the head and the engaged threads.

To accurately determine sheet metal screw sizes for any project, follow a logical process. First, assess the total thickness of the materials being joined. The screw's length should be sufficient to penetrate the bottom material by at least three full threads, but not so long that it protrudes obstructively. Next, consider the required diameter based on the load; heavier loads demand larger diameters. Finally, factor in the material type (e.g., aluminum vs. stainless steel) and environment (e.g., outdoors, corrosive) to select the appropriate screw material and plating, such as zinc or galvanized coating.

In conclusion, mastering sheet metal screw sizes is not about memorization but about understanding the principles of diameter, length, thread engagement, and application-specific requirements. By leveraging the appropriate charts and following a deliberate selection process, you can ensure every fastened joint is robust, reliable, and built to last. Always consult engineering specifications or industry standards for critical applications to guarantee the highest level of safety and performance.

content is empty!