ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 0 Author: Allen Xiao Publish Time: 2025-10-22 Origin: Site

Stereolithography (SLA) 3D printing has revolutionized the manufacturing and prototyping industries by enabling the creation of highly detailed, precise, and smooth-surfaced objects. As an additive manufacturing technology, SLA utilizes a light source, typically a laser or projector, to cure liquid resin into solid layers. The core of this process lies in the materials employed, which directly influence the mechanical properties, aesthetic quality, and functional applicability of the final prints. Understanding the diverse range of materials available for SLA is crucial for engineers, designers, and hobbyists aiming to leverage this technology for various applications, from medical devices to consumer products. This article delves into the specific types of materials used in SLA 3D printing, exploring their characteristics, advancements, and real-world uses, providing a comprehensive overview to guide material selection and innovation.

content:

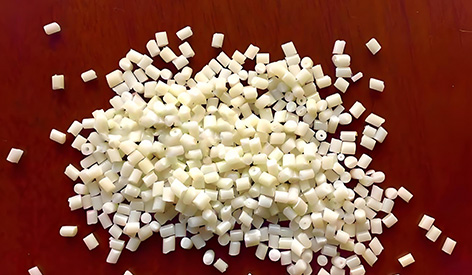

SLA printing materials are the special liquids used in SLA 3D printers to create objects. Think of them like the ink in a printer, but instead of ink, it's a liquid resin that hardens when light touches it. These materials come in different types, depending on what you want to make. For example, if you're building a model that needs to be really strong, you might use a tough resin. Or if you want something that can bend, you'd pick a flexible one. The cool part is that these materials let people make prototypes quickly and test out ideas without waiting for a big factory. As technology gets better, new SLA printer materials are invented, making it possible to print things that are even more amazing and useful.

At the center of SLA 3D printing is something called photosensitive resin. This is a fancy name for a liquid that reacts to light—kind of like how some toys glow in the dark! When UV light (a type of light we can't see) shines on this resin, it turns from a liquid into a solid. This happens because of tiny particles in the resin that link together when the light hits them. Photosensitive resin is what makes 3D resin SLA printing material so popular. It allows printers to make objects with smooth surfaces and fine details, perfect for things like jewelry or dental molds. There are even resins that you can wash with water now, which makes cleanup a breeze. So, in simple terms, this light-sensitive liquid is the superstar that makes SLA printing work so well.

Not all resins are the same—they come in lots of varieties to match what you're making. For instance, flexible materials are like rubber bands; they can stretch and bend without breaking. People use these for things like phone cases or squishy toys because they're soft and durable. On the other hand, ceramic materials are super strong and can handle high heat, almost like real pottery. They're great for making dishes or parts that need to last a long time. Then there's the basic 3D resin SLA printing material, which is good for everyday projects, like school models or simple prototypes. It's affordable and easy to use, with minimal shrinking so your prints come out just right. By picking the right resin, you can make almost anything you imagine!

Imagine if you could print an object that's both hard and soft in different spots—well, with a multi material SLA printer, you can! These printers are like super-machines that use more than one type of resin at a time. They might have separate tanks for different materials or mix them together as they print. This lets you create things with multiple colors or textures all in one go. For example, you could make a tool handle that's grippy and soft but has a hard core. Multi-material SLA printers are pushing the limits of 3D printing, making it faster and more creative for jobs in medicine or design. Even though they can be trickier to use, they open up a world of possibilities for building complex items without putting pieces together afterward.

Besides the common types, there are some really unique SLA materials for special jobs. One awesome example is 3D SLA printed magnetic materials. These resins have tiny magnetic bits mixed in, so you can print objects that stick to magnets—like fun fridge decorations or parts for science projects. Another interesting one is ceramic materials, which we mentioned earlier. They're not just for looks; they can be fired in a kiln to become even stronger, just like traditional ceramics. These specialized SLA printer materials show how creative 3D printing can get, helping people in fields like engineering or art make things that were once impossible. As scientists keep experimenting, we might see even crazier materials, like ones that conduct electricity or are safe for the human body.

In the end, the materials used in SLA 3D printing are what make it so versatile and fun. From photosensitive resin that hardens with light to flexible and ceramic options, there's a material for almost every project. Innovations like multi-material SLA printers and special mixes for magnetic parts keep making this technology better and more exciting. By learning about these materials, you can see how 3D printing is changing the way we build and create things.

content is empty!