ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-10-22 Origin: Site

Stereolithography, commonly known as SLA 3D printing, has revolutionized the world of additive manufacturing by enabling the creation of high-resolution, intricate parts with exceptional surface quality. This technology is widely adopted across industries such as healthcare, automotive, and consumer goods for its precision and versatility. In this comprehensive guide, we will explore the fundamentals of SLA printing, delve into its key components, and highlight its advantages over other methods. By understanding the nuances of SLA, you can make informed decisions for your prototyping and production needs. Let's dive into the details of this innovative approach to 3D fabrication.

content:

Let's start with the name. SLA full form in 3D printing is Stereolithography. That’s a big word, but it just means "solid printing." It was one of the very first kinds of 3D printing invented. Think of it as a high-tech way to make solid objects by using light to harden a special liquid resin, one super-thin slice at a time. This process is perfect for creating models that need to be very smooth and have lots of tiny details.

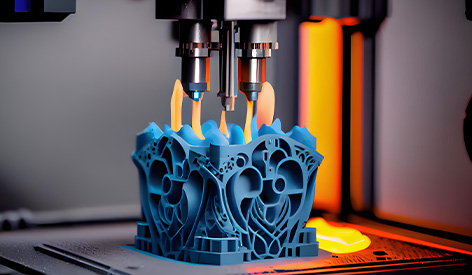

The SLA 3D printing process involves a series of precise steps that transform digital designs into physical objects. It begins with a 3D model created in CAD software, which is sliced into thin layers using specialized software. The printer then directs a UV laser or projector onto a vat of photopolymer resin, curing each layer sequentially. As the build platform moves, additional layers are added until the part is complete. Post-processing steps, such as washing in isopropyl alcohol to remove excess resin and curing under UV light to enhance strength, are crucial for achieving optimal results. This method excels in producing parts with high dimensional accuracy and minimal layer lines, which is why it's favored for detailed prototypes and end-use components. Understanding this workflow helps users optimize designs for better performance and efficiency.

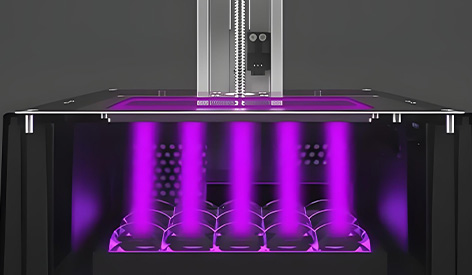

An SLA printer consists of several critical components that work in harmony to deliver precise outputs. At its core, the system includes a build platform, a resin vat, a UV light source (such as a laser or LCD), and a control system. The build platform lowers into the resin vat, and the UV light selectively cures the resin according to the sliced model. High-quality SLA printers often feature adjustable settings for layer height and exposure time, allowing users to balance speed and resolution. Additionally, advancements like heated vats and automated resin handling have improved consistency and ease of use. When selecting an SLA printer, factors such as build volume, resolution, and compatibility with various SLA printing materials should be considered to match specific project requirements. This hardware is designed to support a wide range of applications, from dental models to engineering prototypes.

SLA printing materials play a pivotal role in determining the properties and performance of printed parts. These materials are typically photopolymer resins that come in formulations tailored for different needs, such as standard, tough, flexible, or castable varieties. For instance, standard resins offer high detail and smooth surfaces, while engineering-grade materials provide enhanced mechanical properties like impact resistance or heat tolerance. Recent innovations include biocompatible resins for medical devices and ceramics-filled options for durability. When choosing SLA printing materials, it's essential to consider factors like curing time, shrinkage, and post-processing requirements to achieve desired outcomes. By leveraging the right resin, users can produce functional prototypes, molds, and even end-use parts that meet stringent industry standards.

SLA prototyping is renowned for its ability to produce accurate and visually appealing models that closely resemble final products. This makes it a go-to choice for industries like aerospace, where components must fit precisely, or jewelry design, which demands intricate details. In SLA prototyping, designers can quickly validate concepts, test form and fit, and conduct user feedback sessions without the high costs of traditional tooling. The technology's high resolution allows for the creation of features as fine as 0.05 mm, enabling the simulation of complex assemblies. Moreover, SLA prototypes can be used for secondary processes like painting or metallization to enhance aesthetics. As a result, businesses save time and resources while accelerating innovation cycles through iterative testing and refinement.

You might hear about another type of 3D printing called SLS. So, what's the deal with SLA vs SLS? It’s all about what they use to build things.

SLA uses a liquid resin that is hardened by light.

SLS uses a powder (like fine sand) that is melted together by a laser.

SLA is usually better for making super smooth and detailed objects. SLS is better for making parts that need to be very strong and durable, like hinges or gears. It's like comparing a fine-tipped pen (SLA) to a strong glue gun (SLS)—both are useful, but for different tasks.

So, what are the main advantages of SLA 3D printing?

Super Detailed: It makes the smoothest and most detailed 3D printed objects you can find.

Lots of Choices: There are many different "resin inks" to choose from, depending on what you need.

Fast for Small Things: For smaller objects, it’s a very quick way to go from an idea to a real thing.

Saves Money: It’s cheaper than building a special mold or machine for just one prototype.

SLA printing is an awesome technology that uses light to turn liquid resin into solid objects. It's perfect for making detailed SLA prototype models and final products with a super smooth finish. While SLA vs SLS is a common question, remember that SLA is your go-to for detail and smoothness. The whole SLA 3D printing process is like a precise, layer-by-layer dance of light and liquid.

content is empty!