ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 0 Author: Allen Xiao Publish Time: 2025-10-22 Origin: Site

Additive manufacturing, commonly known as 3D printing, has revolutionized prototyping and production across industries. Among the various technologies available, Stereolithography (SLA) and Selective Laser Sintering (SLS) stand out as popular choices for creating complex parts. While both methods fall under the umbrella of rapid prototyping, they differ significantly in principles, applications, and outcomes. Understanding the distinctions between SLA and SLS is crucial for selecting the right technology based on project requirements, such as surface quality, mechanical strength, and production speed. This article delves into a detailed comparison of SLA and SLS, covering aspects like surface finish, strength, printer mechanisms, and mechanical properties, to help engineers and designers make informed decisions.

content:

Imagine you're building a tiny, detailed model of a dragon.

SLA Printing is like using a magical tracing pen. The printer has a vat of special liquid plastic (called resin). A super-fine laser beam acts like the pen, drawing one thin slice of the dragon on the surface of the liquid. Wherever the laser touches, the liquid turns solid. The platform then lifts up, and the laser draws the next layer right underneath the first one. It keeps doing this until your solid plastic dragon is complete!

SLS Printing is more like building a sandcastle with a laser. The printer has a bed of super-fine plastic powder (like really smooth sand). A powerful laser beam zaps the powder in the shape of your dragon's first layer. The heat from the laser melts the powder particles just enough to fuse them together. Then, a fresh layer of powder is spread over the top, and the laser draws the next layer. The cool part? The unused powder acts as a support, holding up the model as it prints, so you can make really complex shapes.

When we look at SLA vs SLS surface finish, it's all about smoothness.

SLA is the winner for creating super smooth and shiny surfaces. The parts that come out of an SLA printer often look like they were bought from a store. They have very fine details and a glossy finish, making them perfect for detailed figures, smooth jewelry models, or parts that need to look really pretty.

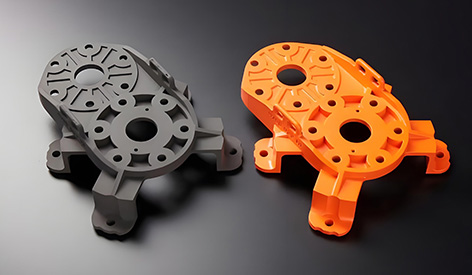

SLS parts come out with a more rough, gritty, or chalky feel. Since they are made from fused powder, they look a bit like a fine sandcastle. You can sand them to make them smoother, but they usually won't get as naturally shiny as SLA parts.

Now, let's talk about SLA vs SLS strength. If you need a part that won't break easily, which printer should you choose?

SLS creates much stronger and more durable parts. Think of it like the difference between a hard plastic toy (SLA) and a tough, flexible Lego brick (SLS). SLS parts are great for things that need to handle stress, like hinges, gears, or protective cases. They can bend a little without snapping.

SLA parts are detailed but can be brittle. If you drop an SLA part on the floor, it might crack or shatter. They are not the best for parts that will be handled roughly or need to withstand a lot of force.

When we compare SLS vs SLA mechanical properties (that's just a fancy way of saying "how strong and tough they are"), SLS is almost always the stronger choice.

So, what's an SLA printer like? It's the machine that does the "magical tracing" we talked about. The main parts are a tank for the liquid resin, a laser that acts like the drawing pen, and a platform that slowly lifts the finished model out of the liquid. The whole SLA printing process is amazing to watch as your object seems to grow out of the liquid!

Engineers and designers often use these printers for "rapid prototyping," which is a quick and cheap way to test a new idea before making a million of them in a factory. When deciding between rapid prototyping SLA vs SLS, here's the simple choice:

Pick SLA if you are making a model to see what it looks like. Is it the right shape? Is it pretty?

Pick SLS if you are making a model to see what it can do. Can it handle being clicked, dropped, or moved around?

The decision between SLA and SLS in additive manufacturing hinges on a thorough evaluation of project needs, including surface finish, strength, and application context. SLA offers exceptional detail and smoothness, making it ideal for visual prototypes and precision parts, whereas SLS provides superior mechanical properties and durability for functional components. By understanding the nuances of sla vs sls, including aspects like sla printer mechanisms and sls vs sla mechanical properties comparison, professionals can optimize their rapid prototyping strategies. As technology advances, both methods continue to evolve, offering even greater possibilities for innovation. Whether for rapid prototyping or end-use production, aligning the technology with specific requirements ensures efficiency and success in modern manufacturing.

content is empty!