2025-11-21 When a customer buys your product, they are not just buying an object. They are buying a promise. A promise that the product is safe. A promise that it is reliable. A promise that it will perform as expected, not just today, but for years to come.For any product that generates heat, or operates in a

Read More

2025-11-21 Pick up a cheap toy. Now pick up a high-end remote control. What is one of the first things you notice? The weight.One feels hollow, light, and insignificant. The other feels solid, substantial, and valuable. This feeling is not an accident. It is a deliberate design choice. It is the result of care

Read More

2025-11-21 Should your design be limited by what a material can do? Or should your material be capable of bringing any design to life?For centuries, designers were constrained by their materials. Wood could only be carved in certain ways. Metal could only be bent so far. But the invention of modern polymers ch

Read More

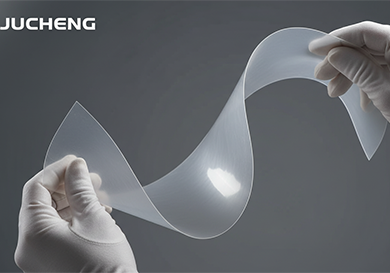

2025-11-21 Your new product is finished. The housing is made from a beautiful, glossy, hard plastic. It feels solid and rigid. It looks like a high-quality item. Then, the first time a customer drops it, it shatters.The customer is angry. Your brand's reputation is damaged. You have a costly warranty problem o

Read More

2025-11-21 What is the most important element in a room? Is it the furniture? The color of the walls? For many great designers, the answer is simpler. It is light.How light enters a space, how it is shaped, and how it is diffused defines our entire perception of that space. It creates mood. It directs our atte

Read More

2025-11-21 Your new industrial pump is assembled. All the bolts are tightened to the correct torque. You turn it on. And it leaks. A tiny, persistent drip from a flange connection.The cause is almost always the same. The gasket. The small, seemingly simple piece of flexible plastic between the two hard metal f

Read More

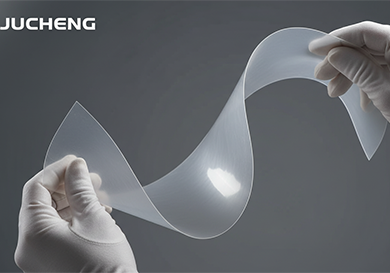

2025-11-21 Your next product needs a "personality." Does it need to be flexible and forgiving, like a rubber gasket? Does it need to be unbreakably tough, like a power tool housing? Or does it need to be rigid and unflinching, like a support chassis?The world of plastics offers you all these personalities. But

Read More

2025-11-20 The simulation was perfect. Your Finite Element Analysis (FEA) showed that the new machine guard, made from clear PET plastic, could easily withstand the expected impacts. The design was approved.The first prototype arrives. It looks beautiful. It is crystal clear and rigid. You install it on the ma

Read More

2025-11-20 What is the difference between a cheap-feeling product and a premium one? It is not always the price. It is not always the complexity. Often, it is simply the "feel."The way a product feels in your hands. The sound it makes when you set it down. The quality of its surface. These small sensory detail

Read More

2025-11-20 Your new protective case has a beautiful foam insert. It holds the product perfectly. But after a few uses, a disaster. The foam starts to tear. It feels lifeless. It loses its bounce. It no longer holds the product securely.What went wrong? You specified a foam material. But not all foams are creat

Read More