ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-10-14 Origin: Site

Have you ever seen a bicycle, a playground slide, or a car with a really shiny, colorful, and tough finish? Chances are, you were looking at something that got a powder coat! This is a super cool way to paint things that makes the color last a long, long time. Let's break down how it works and all the different machines involved, in a way that's easy to understand.

content:

Imagine if you could paint something using a dry powder instead of a wet, drippy liquid. That’s exactly what powder coating is! It's like sprinkling colored, magnetic dust onto a metal object.

First, the metal object is cleaned. Then, a special gun is used to spray the powder. This gun gives the powder a tiny positive electric charge. The metal object is given a negative charge. You know how opposite sides of a magnet attract? It's the same idea! The positively charged powder is magically pulled onto the negatively charged metal, sticking to it evenly.

Finally, the object is baked in a big oven, kind of like a pizza. The heat melts the powder, which then flows into a smooth, hard, plastic-like shell. This shell is much tougher than regular paint. It doesn't chip or scratch easily, and it's great for the environment because it doesn't have the smelly chemicals that regular spray paint does.

So, what kind of powder coating equipment do you need to do all this? It's not just one machine; it's a whole team working together!

The main players are:

The Spray Gun: This is the tool that sprays the powder and gives it that electric charge.

The Powder Feeder: This is like the gun's backpack, holding the colored powder and feeding it to the gun.

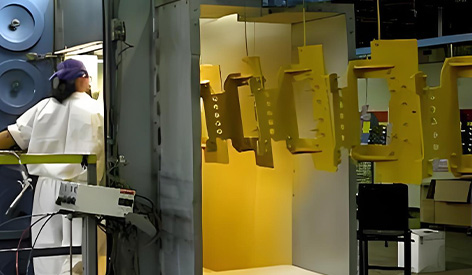

The Spray Booth: This is a small room or box where the spraying happens. It keeps the powder from getting everywhere.

The Curing Oven: This is the big oven that melts the powder to create the final hard coat.

If someone wants to try powder coating at their workshop or small business, they don't have to buy each piece separately. They can buy a powder coating equipment package. This is like a starter kit that has everything you need in one box. It makes setting up much easier and faster, so you can start your projects without any hassle.

Not every place that does powder coating is the same. They need different tools for different jobs.

Commercial Powder Coating Equipment: Think of a small bike repair shop or an artist who paints metal sculptures. They need commercial powder coating equipment. This type is perfect for smaller jobs. The machines are often smaller, easier to move around, and don't cost a fortune. They are great for working on lots of different small projects.

Industrial Powder Coating Equipment: Now, imagine a huge factory that makes hundreds of car parts every day. They need industrial powder coating equipment. This is the heavy-duty stuff! These machines are giant, fully automated, and built to run all day long without stopping. They often use robot arms to spray the powder perfectly every single time.

Some things are tricky to paint because of their shape. That's why there are special machines.

Alloy Wheel Powder Coating Equipment: Car wheels are a great example. They have lots of curves and detailed designs. Alloy wheel powder coating equipment is made just for this. It often has a spinning table that slowly turns the wheel while it's being sprayed. This makes sure every single nook and cranny gets covered with powder, giving it a perfect, even coat.

Automatic Powder Coating Equipment: For the biggest factories, speed and consistency are key. Automatic powder coating equipment does almost all the work by itself. Using computers and robots, it can paint part after part exactly the same way, with very little help from people. This is how things like washing machines and lawnmowers get their perfect finish.

Professional Powder Coating Equipment: Some people are real experts and need the best tools for very detailed work. Professional powder coating equipment is the top-of-the-line gear. It gives the user super precise control over how the powder is sprayed, which is important for expensive or one-of-a-kind projects.

One of the best parts about powder coating is the amazing number of powder coat colors you can choose from! It's not just basic red, blue, and green. You can get metallic finishes that look like polished metal, glittery sparkles, or even textures that feel like leather or wrinkled paper. These colors are designed to stay bright and beautiful for years, even if the object is left outside in the sun and rain.

In summary, powder coating technology offers a versatile and efficient approach to surface finishing, with equipment options tailored to various scales and specialties. From commercial and industrial systems to specialized setups for alloy wheels and automated processes, each type of equipment brings unique advantages. Powder coating equipment packages simplify implementation, while a diverse range of powder coat colors enables customization. By understanding these elements, businesses can select solutions that align with their operational goals, enhancing productivity and quality.

content is empty!