ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 0 Author: Allen Xiao Publish Time: 2025-10-22 Origin: Site

Stereolithography (SLA) has revolutionized the field of additive manufacturing, offering unparalleled precision and efficiency for creating complex prototypes and end-use parts. As a cornerstone of rapid prototyping, SLA technology utilizes photopolymer resins cured by ultraviolet light to produce high-resolution models. This article delves into the critical facets of SLA, including its materials, services, and comparisons with other technologies like SLS, providing a comprehensive overview for engineers, designers, and manufacturers seeking to leverage this innovative approach. By exploring SLA prototype parts, services, and materials, we can better understand its advantages and applications in today's competitive market.

content:

Let's break down the big name: Stereolithography (SLA). "Stereo" means solid, "litho" means stone, and "graphy" means writing. So, it's basically "writing solid objects." In SLA rapid prototyping, the word "rapid" is key because it means "fast." This is a super-fast way to make a model of a new idea.

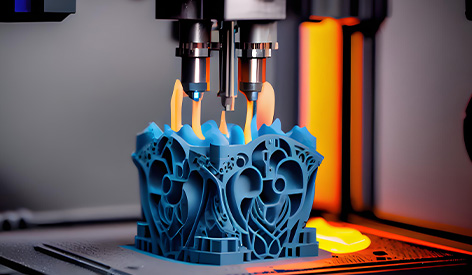

Here's how it works: a machine has a small tub filled with a special liquid plastic that is sensitive to light, kind of like how your skin is sensitive to sunlight. A powerful, super-precise laser beam (our "light pencil") draws the shape of the object onto the surface of the liquid. Wherever the laser touches, the liquid turns solid. The platform then moves down just a tiny bit, and the laser draws the next layer, sticking it to the one before it. It keeps doing this, layer by layer, until the whole object is built from the bottom up. This lets inventors and engineers quickly test their ideas without having to build expensive molds.

The objects made by this process are called SLA prototype parts. Because the laser is so precise, these parts can have incredible details. Imagine making a tiny castle with super small windows and a spiral staircase inside, or a model of a dinosaur with every single tooth perfectly shaped. That's the kind of detail SLA can create. These aren't just for show; companies use them to see if parts fit together, to test how a new design works, and even to create masters for making molds, like the ones used to make chocolate shapes!

Not every company has its own SLA machine. They are very advanced and can be expensive. That's why many people use an SLA prototype service. This is like using a special printing company, but instead of printing posters, they print 3D objects for you. You just send them your computer file, and they handle all the complicated printing and cleaning for you. This is a great help for small businesses or students who have a brilliant idea but don't have the machine to make it real.

The magic liquid used in the printer is the SLA prototype material. It's not just one type of liquid; there are many different kinds, just like there are many types of clay or Lego bricks. Some of these liquids turn into a hard, strong plastic, perfect for making parts that need to be tough. Others can turn into a flexible, bendy material, almost like a rubber band. There are even special ones that are safe to use inside the human body for a short time, which doctors can use to plan for surgery. Choosing the right "ingredient" is super important to make sure the final object is just right for the job.

You might have heard of other 3D printers that use plastic filament, like a spaghetti string. But how is SLA different from another technology called SLS? It's like comparing two different chefs in a kitchen.

SLA (Our "Light Chef"): Uses a vat of liquid and a laser to harden it. It's fantastic for making super smooth and highly detailed objects, like a detailed action figure. However, sometimes it needs little "support sticks" to hold up parts of the object while it's being printed, which have to be broken off later.

SLS (The "Powder Chef"): This method uses a laser to melt and fuse tiny grains of plastic powder together. The cool thing about the "Powder Chef" is that the unused powder itself acts as a support, so you can make much more complicated shapes, like interlocking chains, without any extra support sticks. The objects it makes are usually very strong and durable, but the surface can feel a bit sandy instead of super smooth.

So, if you need something really detailed and smooth, you pick the "Light Chef" (SLA). If you need something very strong and with crazy-complex shapes, you might pick the "Powder Chef" (SLS).These are the differences between sla and sls.

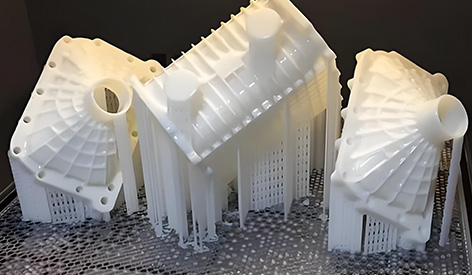

The whole journey of SLA printing is like a mini-adventure for your idea. It starts as a drawing on a computer. That file is then sent to the printer, which uses its laser to carefully "draw" the object in the liquid. After the printing is done, the object is rinsed in a special liquid bath to clean off the gooey residue, kind of like washing off muddy feet. Finally, it's placed under a bright UV light (like a tanning bed for plastic) to finish hardening and become strong. This process allows people to turn ideas into real objects super fast, which is why it's a favorite tool for creators everywhere.

In conclusion, SLA prototyping stands as a powerful tool in modern manufacturing, driven by its ability to produce precise, high-quality parts rapidly. From SLA prototype parts and services to material innovations and comparisons with SLS, this technology offers diverse benefits that cater to various industry needs. As SLA printing continues to evolve, it will likely play an even greater role in accelerating product development and fostering innovation. By staying informed about these aspects, professionals can make strategic decisions that enhance their prototyping workflows and competitive edge.

content is empty!