ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-12-17 Origin: Site

What is a product's first language? It is not the user manual. It is not the marketing copy on your website. A product's first language is visual. It is the story it tells across a room, before a single word is spoken or a single touch is made.

Does it look cheap or premium? Is it elegant or clumsy? Does it inspire curiosity or indifference? This first conversation with your customer is often the most important one.

In product development, the tool you use to perfect this language is the Visual prototypes. It is not just a model. It is your product's first ambassador to the world.

content:

A visual prototype has one primary mission: to look and feel exactly like the final, mass-produced product. It is a high-fidelity replica of your design vision.

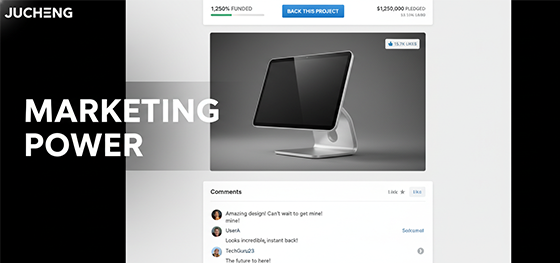

Why is this so important? It is a powerful tool for communication. For a startup, a perfect visual prototype is the most powerful tool for persuading investors. It turns a slideshow into a tangible, believable product.

For a marketing team, it is the star of the show. It can be used for professional product photography and videos long before the first production parts are ready. This allows you to launch your marketing campaigns and build excitement early.

For a design team, it is the ultimate reality check. It is the only way to truly evaluate the aesthetics of a product. To see how the curves catch the light. To feel how the different textures work together.

Creating a perfect visual prototype requires technologies that are masters of detail and surface quality.

The first tool is SLA (Stereolithography) 3D printing. SLA uses a laser to cure a liquid resin into a solid object. Its defining feature is its incredible resolution. It can produce parts with razor-sharp details and a very smooth surface, right out of the machine. This is perfect for creating a single, highly detailed master pattern.

The second tool is Vacuum Casting. This is the ideal choice when you need a small batch (5 to 50) of identical visual models, perhaps for a sales team or a focus group. We take that perfect SLA master pattern and create a flexible silicone mold from it. We then cast a polyurethane resin into the mold. This process creates parts with a flawless surface finish that is often indistinguishable from a final injection molded part.

A raw part from a machine is a body without a soul. The soul of a visual prototype comes from the finishing department. This is where craftsmanship and artistry take over.

The journey to a perfect finish is a painstaking, multi-step process. It starts with meticulous sanding. A skilled technician will sand the entire part with progressively finer grits of sandpaper until the surface is perfectly smooth, with no hint of layer lines or tool marks.

Next comes painting. This is done in a professional, dust-free spray booth. Multiple layers of primer, color, and clear coat are applied to achieve the exact color, gloss level, and texture specified by the designer. We can create a high-gloss finish that looks like a luxury car, or a soft-touch matte finish that feels warm and inviting.

Finally, the graphics are applied. Using silkscreening or pad printing, we can add your company's logo, button icons, and any other text with perfect sharpness and alignment. This is the final detail that brings the product to life.

Most products are not a single part. They are a complex assembly of multiple components. A great visual prototype must reflect this.

This means every part must be finished to the same high standard. It also means they must fit together perfectly. The "fit and finish" is a key indicator of quality.

The gap between two mating parts must be perfectly even. The seam should be almost invisible. A button must sit perfectly flush in its opening. A transparent lens must fit seamlessly into its housing.

Achieving this level of assembly perfection in a prototype requires incredible precision in both the manufacturing and the finishing stages. It is the ultimate test of a prototyping partner's skill and attention to detail. At JUCHENG, this is the level of quality we live for.