ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-12-17 Origin: Site

Your CAD file is a blueprint for a journey. You upload it to a manufacturer, and a few days later, a physical part arrives at your door. But what happens on that journey? What are the critical steps between your click and your part?

Understanding this journey is the key to a successful project. So, what is rapid prototyping process? It is not a single "print" button. It is a carefully managed, multi-stage workflow, designed for speed and quality.

This guide will pull back the curtain on that workflow. We will walk you through the four essential stages of the modern Rapid prototyping process.

content:

The journey does not start in the factory. It starts with your design. But before a single machine is turned on, a critical, often invisible, step must happen: the Design for Manufacturability (DFM) check.

This is the most valuable part of any professional prototyping service. A simple online vendor might just take your file and print it, flaws and all. A true manufacturing partner stops and thinks.

At JUCHENG, our engineers provide a Free DFM Review for every project. We are your second set of expert eyes. We will look at your medical device housing and ask: "This wall is too thin for CNC machining, could we thicken it by 0.5mm?" or "This sharp internal corner will be a stress point, can we add a radius?"

This proactive feedback is the most important part of the entire Rapid Prototyping process. It prevents costly errors. It optimizes your design. It is the foundation of a successful part.

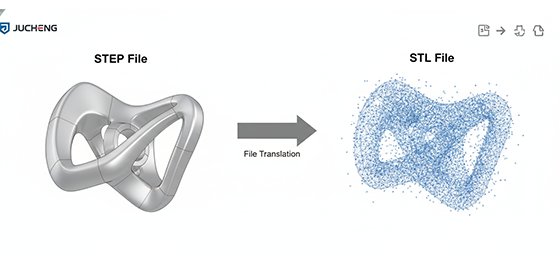

Once the design is confirmed, it needs to be translated into a language the machines can understand. This is the file conversion stage.

Your native CAD file, with all its perfect curves and features, is usually in a format like STEP or IGES. This is great for design, but most manufacturing machines need a simpler language.

For 3D printing, this language is usually STL (Stereolithography). An STL file converts your smooth, curved surfaces into a mesh of millions of tiny triangles. The quality of this conversion is critical. A low-resolution STL file will result in a faceted, ugly print.

For CNC machining, our engineers use special CAM (Computer-Aided Manufacturing) software. This software takes your STEP file and helps the programmer create the "toolpaths"—the precise route the cutting tool will take to carve your part. This is a highly skilled job that blends computer science with a deep understanding of the physical world.

With the machine instructions ready, the creation begins. The part is now built using the technology that was selected during the evaluation stage.

If it is 3D printing, the STL file is sent to the machine, and the part is built, layer by microscopic layer, over several hours or days.

If it is CNC machining, a block of real material is loaded into the machine. The CAM program is loaded, and the machine begins the powerful, precise process of carving away metal or plastic.

This is the most visible part of the rapid prototyping process, but as we have seen, it is only possible because of the critical "invisible" work that came before it.

A part that comes directly off the machine is rarely a finished part. The final stage of the journey is post-processing. This is where the part gets its final look and feel.

For a 3D printed part, this involves removing support structures, sanding the surface to remove layer lines, and often, painting or applying a clear coat to achieve the desired cosmetic finish.

For a CNC machined part, it means deburring all the sharp edges to make it safe to handle. It might also involve secondary operations like bead blasting for a matte texture, or anodizing for color and protection.

This final, often manual, stage is where craftsmanship makes a huge difference. A professional finishing job can turn a good prototype into a great one. It is the final polish on your idea before it is sent out into the world.