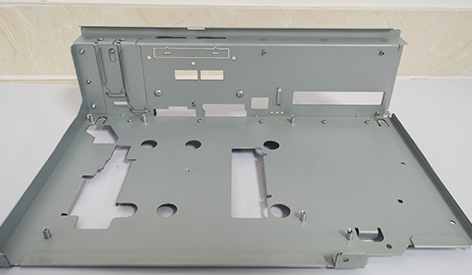

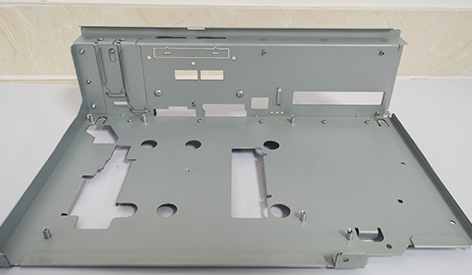

2023-12-06 Sheet metal prototyping involves the creation of prototype parts or components using various sheet metal fabrication processes. These processes are chosen based on factors such as material type, part complexity, tolerances, and the desired end-use application. Here are some common processes used in

Read More

2023-12-04 Vacuum casting and reaction injection molding (RIM) are both processes used for the production of plastic or polyurethane parts, but they have distinct differences. Here are the key differences between vacuum casting and reaction injection molding: Process Principle:Vacuum Casting: Involves creating

Read More

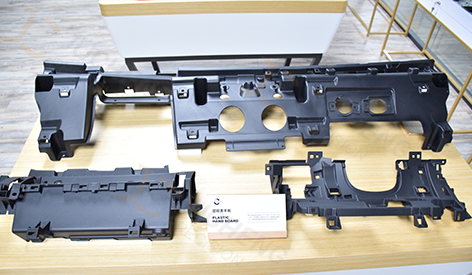

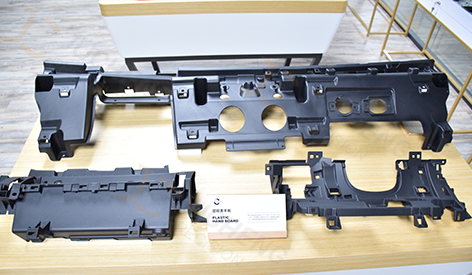

2023-11-29 When making automobile plastic parts using reaction injection molding (RIM), several factors should be considered to ensure the production of high-quality components. Here are some key considerations: Material Selection: Choose a suitable RIM material for automotive applications, considering factors

Read More

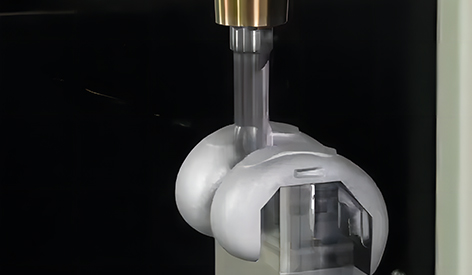

2023-11-27 What are the difficulties in processing aluminum alloy prototypes with CNC machines?

Read More

2023-11-22 Achieving a machining accuracy of 0.01 for precision equipment parts requires careful attention to various factors throughout the CNC machining process. Here are some precautions to ensure high precision: Machine Calibration and Maintenance:Regularly calibrate and maintain CNC machines to ensure acc

Read More

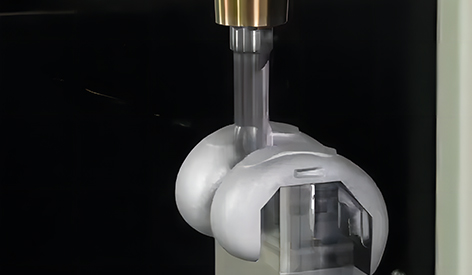

2023-11-20 What should we pay attention to in 5-axis CNC machining of knee joint bones for precision medical device parts?When performing 5-axis CNC machining for precision medical device parts such as knee joint bones, several critical considerations should be taken into account to ensure accuracy, quality, a

Read More

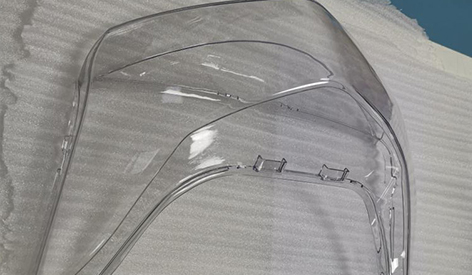

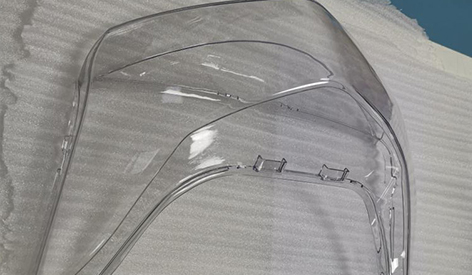

2023-11-16 The requirements for 5-axis CNC machining of car light housings include: Complex Geometry: Car light housings often have intricate shapes and curves. 5-axis CNC machining allows for simultaneous movement along multiple axes, facilitating the processing of complex geometries.High Precision: Car light

Read More

2023-11-08 Vacuum casting is a rapid prototyping technique that can be used to create prototypes of beauty instruments. Here are the advantages and precision of vacuum casting for this purpose:Advantages: High-Quality Surface Finish: Vacuum casting produces prototypes with smooth and high-quality surface finis

Read More

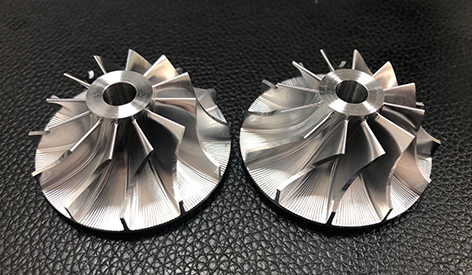

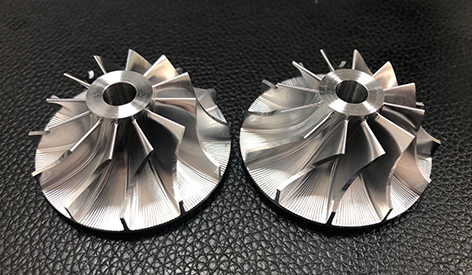

2023-11-06 Rapid prototyping technology offers several advantages for automotive impellers: Faster Development: Rapid prototyping significantly reduces the time required to design, test, and iterate impeller designs. This accelerates the product development cycle. Cost Savings: It minimizes the need for expens

Read More

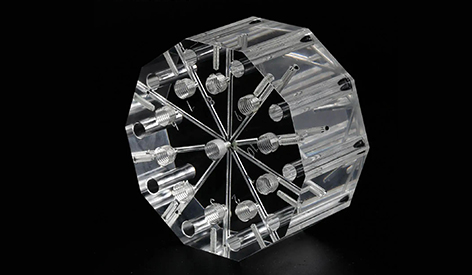

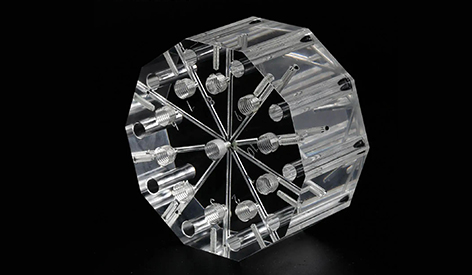

2023-11-02 CNC machining acrylic for transparent applications requires careful handling to achieve a clear and polished finish. Here are detailed instructions for CNC machining acrylic for transparency:1. Material Selection:Choose high-quality transparent acrylic sheets with minimal defects or imperfections.2.

Read More