ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-12-08 Origin: Site

A sculptor carves a statue from a block of marble. Is it finished when the last chip of stone falls away? No. The real work has just begun. The work of sanding, polishing, and bringing the stone's inner soul to life.

A 3D printer creates a part from a digital file. Is it finished when the machine beeps? Absolutely not. The object that comes out of the machine is only a raw form. It is a body without a soul.

That soul is awakened on the finisher's workbench. This is the world of 3D printing post processing. It is a world where art meets engineering, and where a simple print is transformed into a finished product.

content:

The first step of any great finish is a perfect, clean surface. A part fresh from an Industrial 3D Printing machine is never truly clean.

A resin-based SLA part is coated in sticky, uncured liquid. It must be carefully washed in a solvent bath, like isopropyl alcohol, to remove all residue.

A powder-based SLS or MJF part is encased in a block of loose powder. It must be excavated like a fossil. Then, it goes into a bead blasting cabinet. A high-pressure stream of air and tiny glass or plastic beads is used to clean off every last speck of stubborn powder, even from intricate internal channels.

This cleaning stage is critical. Any leftover resin or powder will ruin all subsequent steps. It requires professional equipment and a meticulous attention to detail.

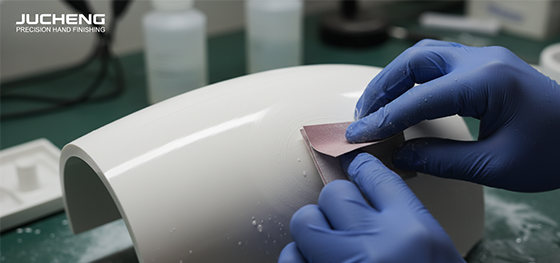

Even a clean part is not yet smooth. All 3D printing processes, even high-resolution SLA, leave microscopic layer lines or a slightly rough texture. The pursuit of smoothness is an art form.

This is the world of sanding. It is a patient, multi-step process. A skilled technician will start with a coarser grit sandpaper to quickly level the main surface and remove any support marks.

Then, they move to progressively finer grits. 240 grit, then 400, then 600, sometimes all the way to 1000 or more. Each step removes the scratches from the previous one. For parts with complex curves, this must be done by hand with incredible care to avoid changing the part's intended shape.

For some materials like Nylon, a process called Vapor Smoothing can be used. The part is exposed to a chemical vapor that slightly melts the outer surface. This process magically smooths away layer lines, creating a sealed, semi-glossy finish that is close to injection-molded quality.

Once the canvas is perfectly smooth, the real transformation can begin. This is the painting stage.

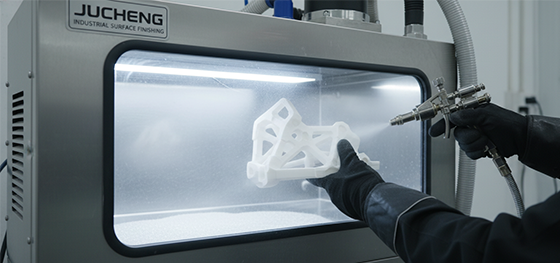

Professional painting of a 3D print is a science. It does not come from a spray can. It happens in a controlled, dust-free spray booth.

First, a special primer is applied. This ensures the topcoat of paint will have a strong, permanent bond with the plastic. After the primer is cured and sanded, the color coats are applied in several thin, even layers.

This is where true artistry comes in. Our finishers can match any Pantone color. They can create a huge range of finishes: a soft-touch matte, a high-gloss "piano" black, a metallic silver, or even a textured finish. Finally, a durable clear coat is applied to protect the color and give the desired gloss level.

This is how a simple white resin print becomes a stunning, market-ready product.

The final step is adding the details that turn a housing into a product.

This can involve dyeing. For SLS or MJF parts, they can be submerged in a hot dye bath to give them a deep, uniform color, which is more durable than paint for parts that will see a lot of wear.

It also includes adding graphics. Using processes like silkscreening or pad printing, we can apply your company's logo, button labels, and regulatory markings with perfect precision.

It can even involve simple assembly. We can install threaded inserts, light pipes, or even assemble multiple 3D printed parts together.

A complete 3D printing post processing service does not just send you a raw part. It sends you a solution. At JUCHENG, we understand that the work is not finished until the part's soul has been fully awakened. We have the full range of tools and, more importantly, the skilled artisans to make that happen.