ㆍPrivacy: We respect your privacy. Here you can find an example of a non-disclosure agreement. By submitting this form, you agree to our terms & conditions and privacy policy.

Views: 1 Author: Allen Xiao Publish Time: 2025-12-09 Origin: Site

Should a sculptor build his statue by adding clay, piece by piece? Or should he carve it from a solid block of marble, removing everything that is not the statue?

This is not just an artistic question. It is the fundamental philosophical choice at the heart of modern manufacturing. It is the core of the cnc machine vs 3d printer debate.

Choosing between them is not about which is "better." It is about understanding their completely different philosophies and choosing the one that aligns with your project's mission. This guide is a look at those two opposing, yet equally powerful, worldviews.

content:

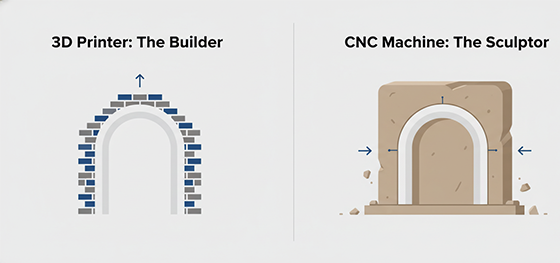

A 3D printer is a builder. Its philosophy is "additive manufacturing." It starts with nothing. It meticulously adds material, layer by tiny layer, to "grow" a part from a digital file. It is an incredibly efficient process, using only the material that is needed for the final part.

A CNC machine is a sculptor. Its philosophy is "subtractive manufacturing." It starts with a solid block of material, larger than the final part. It then uses a spinning cutting tool to carve away everything that is not the part. It is a process of revealing the final form from within a raw block.

These two opposing philosophies give each technology a unique set of superpowers.

In the battle of geometric complexity, the 3D printer wins. And it is not even a close fight.

Because it builds layer by layer, a 3D printer can create "impossible" geometries. It can create hollow parts. It can create parts with intricate internal channels. It can create organic, lattice-like structures that look more like bone than a machine part.

A CNC machine is limited by its tools. A physical cutting tool cannot reach inside a part to carve out a complex channel. If the tool cannot touch the surface, it cannot be cut.

So, for a mission that requires extreme geometric freedom, like a medical implant with a porous surface or a mold insert with conformal cooling channels, Industrial 3D Printing is the undisputed champion.

In the fight for ultimate precision and surface quality, the CNC machine is the reigning king.

The layered nature of 3D printing, even on the best industrial machines, means there will always be microscopic layer lines. The final part's accuracy is good, but it has its limits.

A CNC machine, on the other hand, is a master of precision. It can hold tolerances that are often 5 to 10 times tighter than a 3D printer. It can create surfaces that are optically smooth, flat, and perfect. A spinning end mill can produce a finish that feels like glass.

So, for a mission that requires a part to have a perfect sealing surface, a bearing bore with a critical tolerance, or a flawless cosmetic finish, the CNC machine is almost always the superior choice.

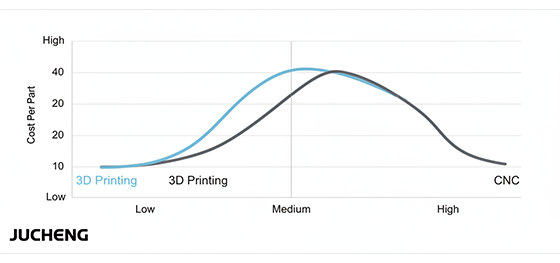

The final battle is about cost. And here, the winner depends entirely on the quantity.

A 3D printer has almost zero setup cost. You can send a file and start printing immediately. A CNC machine requires a skilled operator to program the toolpaths and set up the machine. This means the cost of the very first part is higher for CNC.

However, once a CNC machine is set up, it is often much faster at making each subsequent part. 3D printing time is mostly based on the part's volume and height, regardless of how many you are making.

This creates a "crossover point." For very low quantities (1-10 parts), 3D printing is usually cheaper. But as the quantity increases (50+ parts), the speed of the CNC machine takes over, and it becomes the more cost-effective option per part.

So, in the battle of cnc machine vs 3d printer, who wins? The customer.

The modern, intelligent approach is not to see them as enemies, but as teammates. This is called "hybrid manufacturing."

A designer can use a metal 3D printer (DMLS) to create a part with an incredibly complex internal structure. This part will have the amazing geometry from the additive world. But its surface will be slightly rough.

Then, that same part is put into a 5-axis CNC machine. The CNC does not have to do all the hard work of removing a huge block of material. It just comes in at the end to perform the final, critical finishing touches. It machines the sealing surfaces to a mirror finish. It drills the mounting holes to a perfect tolerance.

This is the best of both worlds. The complexity of the builder and the precision of the sculptor. A manufacturing partner like JUCHENG, with expertise and advanced capabilities in both technologies, can offer this powerful, integrated solution. We do not try to sell you a process. We help you build the best possible part, using whatever tools are necessary.